sheet metal welding plug holes Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an. Problems that can arise during metal slitting include poor edge quality, edge burr, edge wave, camber, crossbow, knife marks, and slit width that is out of specification.

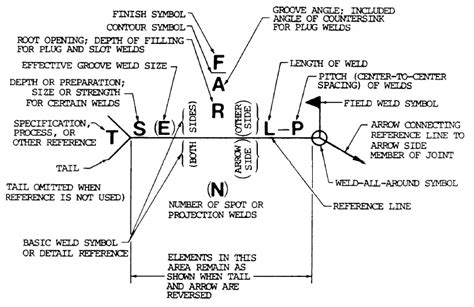

0 · welding symbol for plug weld

1 · plug welding techniques

2 · plug weld vs slot

3 · plug weld vs fillet

4 · plug weld size chart

5 · plug weld not completely filled

6 · plug weld in steel structure

7 · plug weld hole size chart

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .

Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

A plug weld, or rosette weld, is a welding method that joins overlapping metal sheets by filling pre-cut circular holes with molten metal, creating strong, discreet joints. Widely used in automotive and construction . Protect your vehicle from rust and debris with the Eastwood Sheet Metal Plug Kit. It's easy to install and provides a clean, professional look. An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo. The kit includes three sizes of 18 gauge plugs to allow you to fill various sizes of holes. The step drill bit and plugs are designed for a precise fit. Simply drill the hole to the size plug.

Plug welding involves joining two overlapping sheets of metal by welding through the top sheet to the bottom sheet, creating a strong and concealed bond. This method is commonly used in automotive and sheet .

Free Shipping - Bob Drake Weld-In Hole Repair Kits with qualifying orders of 9. Shop Patch Panels at Summit Racing. Off 0 / Off 0 / Off 00 - Use Promo Code: CYBER. Vehicle/Engine Search Vehicle/Engine . ok, im not a professionally welder lol. My little mig welder has left a few pin holes in my sheet metal repair. What is good to fill these in with before laying filler over it? I've heard bondo glass is good, and I've heard just seam sealer will work. I don't want the filler to start bubbling a few years down the road. thanks

metal fabrication jobs ottawa

welding symbol for plug weld

I use 1/4" holes for sheet metal and usually 5/16-3/8 holes for light plate. There actually is a chart that can be found online for structural rosette welds. I have one in one of my structural design books but i have seen the chart on line. If you are trying to clamp a panel for plug welds, self tapping sheet metal screws and a selection of various vise grip type clamps are usually how it's done. . He attaches panels with sheet metal screws and then fills the small 1/8" hole followed by the 1/4" flange hole to make a strong plug weld. Monocoque Metalworks Around the 1:30 mark or . The main difference between plug welds and slot welds is the shape of the hole that is drilled into the metal. A plug weld has a round hole, while a slot weld has an elongated hole. How is a plug weld made? A plug weld is made by drilling a hole through one member of a joint, with the hole being slightly larger than the diameter of the . How to Plug Weld Sheet Metal? To plug weld sheet metal, first, make sure both pieces of metal are clean and fit tightly together. Next, drill a hole through the top piece of metal and into the bottom piece. Insert a weld plug into the hole and weld around the edges of the plug to secure the pieces together.

Testing plug weld hole sizes to see which is best on sheetmetal Strong Hand Tools AGK320 Hole Plug Magnet, Hands Free Weld, Pivoting Magnetic V-Pad Base, Spring Loaded Arm, Heat Dissipating Copper Pad, 5.5" Length. .48 $ 17. 48. . 141 Pcs Plugs in Box Auto Body Black Plastic Hole Plug Button and Flush Mount Sheet Metal Plug Assortment Kit Assorted Set Automotive Body Plug Hole Cap Fits Hole Size 1/2 .

Hey everyone, I've got 62!! 3/8" holes to weld up on my fenders,doors and quarterpanels after removing all the stainless trim. I recall seeing an article in Street Rodder a few years ago about a supplier for weld in mild steel plugs in a few common sizes. Any ideas on where I might find them? The thought of scribing/cutting that many gives me . Hi folks Newbie to welding here about 3 months. I have been playing with clean new metal making various joints with my brand spanking new Clarke 90 gas welder. Using 0.6 wire and hobbyweld gas mix. I have been attempting plug welds through 1.2 steel with a 5 mm hole with not much sucess.

Put it behind the hole and start welding around the periphery of the hole. Weld in a circle and move to the center as you finish up. The back side of the weld will be flat. If the hole you want to weld up is any bigger a good approach is to make a plug of sheet metal the size of the hole. Then just weld the plug into the hole, using tack welds. Plug Welding. Plug welding is a method in which a round hole or slot is filled with a puddle of weld that is used to mate two parts or surfaces together. Plug welding has many drawbacks and isn’t a popular choice. Considerations for plug welding. Time-consuming and difficult to clean High risk of deformation due to the amount of heat required

When fixing and rejoining metal objects, the best technique is welding. For instance, when joining two metal pieces, welding is the best method. However, you cannot apply it in specific conditions. If holes still form in the metal, it’s advisable to use a distinct method. In this stage, a question on how to fill metal holes without welding . Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW. Unlike MIG and TIG, stick welding doesn’t require a shielding gas. Instead, the flux covering on the consumable electrode protects the weld pool but also influences the arc’s characteristics.Eastwood 54820 | Sheet Metal Plug Hole Patch Kit-Eastwood 54820 | Sheet Metal Plug Hole Patch Kit Precisely fill holes from rust, door locks, antennas . the patch in the hole. TIP: Use Eastwood Stitch Weld Magnets (item 20421) to .

A plug weld is exactly what it sounds like, a weld meant to fill a hole by plugging it. A plug weld is done by pressing a solid welding rod into the hole you. Skip to content. About; Contact; Articles; . This is a great video overview . Add small dabs of new material around the perimeter of the hole until it closes over. Plug welding kits include pre-cut blanks in multiple sizes plus a step-style bit for drilling sheet metal. Sheet metal patch – If you lose control of .Ten Pack of 18 gauge 0.75 Inch Replacement Plugs for the Eastwood Plug Hole Kit - Item 54820. These 3/4" sheet metal plugs are designed to be used with the Plug Hole Kit to fill holes from rust, door locks, antennas and more. . Welding; Metal Fabrication; Tools and Shop Equip; Eastwood Concours . Item 54820. These 3/4" sheet metal plugs are . Plug Welding. Plug welding, also known as hole welding, involves joining two metal pieces by filling a hole in the top piece with weld material, which then fuses with the bottom piece. This method creates a strong, durable bond and is commonly used in automotive and manufacturing applications. Spot Welding

Plug welding. Start off by drilling 7.5mm holes in the front sheet of metal at a spacing of normally 25mm to 40mm (or whatever the original spot weld spacing was). Then clamp this sheet onto the back sheet. 7.5mm is a reasonably good hole size for 0.8 or 1.0mm sheet. In this video I share the easy way to fix small holes in sheet metal with a mig welder. This mig welding process works well with rust repair also. The trick . https://www.proshaper.com Our Amazon Storefront: https://www.amazon.com/shop/proshaper Plug weldingChanging it up, in this video Wray goes over plug welding .

I took all the seats out and I need to patch the bolt holes in the floor. They're no larger than 3/8" and I was thinking about welding some small pieces of sheet metal over the top of them but I was worried about how to protect if from rusting on the bottom. I don't have good access to all the holes from the bottom of the bus to paint over them.These 12-gauge welding discs are designed to fill the holes in the heavier gauge metal areas of a car, including the frame and any weight-bearing floor. This 29-piece kit includes sheet metal patches in several conventional hole sizes. The patch itself is slightly undersized to allow it to fit cleanly into the hole, however, the real icing on the cake is the tabs surrounding each circle. . There are some tricks to welding thin sheet metal.Proper welder setup is critical. We are using a Millermatic 211 AutoSet MIG welder with .023 wire. The thinner wire is best for sheet metal. Because we are using an extension cord (240v), we adjusted the AutoSet wire setting to .030 wire.

Strong Hand Tools AGK320 Hole Plug Magnet, Hands Free Weld, Pivoting Magnetic V-Pad Base, Spring Loaded Arm, Heat Dissipating Copper Pad, 5.5" Length. 4.5 out of 5 stars. 704. 100+ bought in past month . 3/8" HSS Spot Weld Cutter Remover Drill Bits Hex Sheet Metal Hole Cutter Remover for Power Drill Spot Welding. 4.5 out of 5 stars. 1,588 . Roadkill's Mike Finnegan is in the Hot Rod Magazine Garage welding holes shut on the firewall of their 1955 Chevy project car using Eastwood Magnetic Copper .

metal fabrication kennewick wa

plug welding techniques

metal fabrication jobs to bid

plug weld vs slot

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. Understanding Sheet .

sheet metal welding plug holes|plug welding techniques