advantages and disadvantages of cnc lathe machine Advantages of CNC Lathe Machines. You’ll quickly discover plenty of benefits of CNC lathe that make these machines an asset in modern manufacturing. Continuous Operation & Consistency . One of the most . Treasures are found all the time, long hidden away and forgotten by time. This list features some of the notable hidden treasures found in attics, walls, garage sales, and thrift stores over the past several years. After learning about these discoveries, you may be inspired to find your own! 1. A lock of George Washington’s hair found in a book.

0 · horizontal cnc lathe disadvantages

1 · disadvantages of cnc lathe machine

2 · different types of cnc lathe

3 · cnc lathe pros and cons

4 · cnc lathe advantages and disadvantages

$150.00

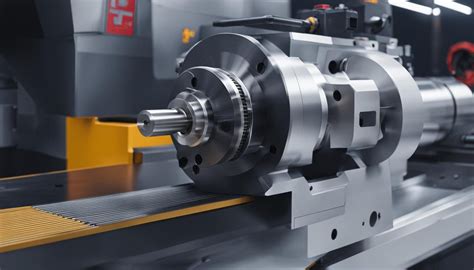

Advantages of CNC Lathe Machines. You’ll quickly discover plenty of benefits of CNC lathe that make these machines an asset in modern manufacturing. Continuous Operation & Consistency . One of the most .High precision and accuracy – CNC lathes craft parts with exact measurements and fine details, ensuring every piece matches the desired specifications. Consistent quality output – They produce items that are exactly alike, making . In the dynamic world of manufacturing, a career as a CNC (Computer Numerical Control) Lathe Machinist is both rewarding and in high demand. CNC Lathe Machinists play a . CNC lathe machines offer high precision and accuracy, making them ideal for industries that require fine tolerances. They provide versatility in working with various materials, from plastics to rigid foam, expanding the .

Discover the advantages and disadvantages of using a CNC lathe machine, including precision, productivity, and potential costs involved. CNC Lathe: These are automated lathes, often guided by computer numeric control (CNC), providing high-precision and mass production capabilities with minimal human intervention. Speed Lathe: Speed lathe machines, with .

Advantages include increased accuracy and improved safety. Disadvantages include high initial cost and limited maneuverability. Lathes are available in manual and CNC versions. Maintenance is required to ensure optimal . Advantages of CNC Lathe Machines. You’ll quickly discover plenty of benefits of CNC lathe that make these machines an asset in modern manufacturing. Continuous Operation & Consistency . One of the most important advantages of CNC lathe is its ability to operate continuously without needing constant manual intervention.

horizontal cnc lathe disadvantages

Advantages of CNC lathes include reduced labor costs, increased productivity, and improved quality control. Disadvantages may include higher upfront costs and the need for specialized training or programming skills.High precision and accuracy – CNC lathes craft parts with exact measurements and fine details, ensuring every piece matches the desired specifications. Consistent quality output – They produce items that are exactly alike, making sure each product is as good as the last. CNC lathe machining can now be said to be a very popular processing technology. Compared with ordinary lathes, CNC lathes between the two are more likely to highlight its advantages. Let's analyze the advantages and disadvantages of these comparisons.

In the dynamic world of manufacturing, a career as a CNC (Computer Numerical Control) Lathe Machinist is both rewarding and in high demand. CNC Lathe Machinists play a crucial role in the production of precision components and parts. This article will guide aspiring individuals on the best route to becoming a CNC Lathe Machinist, offering [.]

CNC lathe machines offer high precision and accuracy, making them ideal for industries that require fine tolerances. They provide versatility in working with various materials, from plastics to rigid foam, expanding the range of possibilities. CNC machines can create simulated models or prototypes, saving time and material costs.Discover the advantages and disadvantages of using a CNC lathe machine, including precision, productivity, and potential costs involved. CNC Lathe: These are automated lathes, often guided by computer numeric control (CNC), providing high-precision and mass production capabilities with minimal human intervention. Speed Lathe: Speed lathe machines, with their high RPM range, are optimal for woodworking, polishing, and metal spinning applications.Advantages include increased accuracy and improved safety. Disadvantages include high initial cost and limited maneuverability. Lathes are available in manual and CNC versions. Maintenance is required to ensure optimal performance. What Are the Advantages of Using a Lathe?

One of the most significant advantages of CNC machining is its high precision and consistency. Unlike traditional machining methods, which rely heavily on manual operation, CNC machining utilizes computer-controlled systems to dictate the movements of machine tools. Advantages of CNC Lathe Machines. You’ll quickly discover plenty of benefits of CNC lathe that make these machines an asset in modern manufacturing. Continuous Operation & Consistency . One of the most important advantages of CNC lathe is its ability to operate continuously without needing constant manual intervention.Advantages of CNC lathes include reduced labor costs, increased productivity, and improved quality control. Disadvantages may include higher upfront costs and the need for specialized training or programming skills.

High precision and accuracy – CNC lathes craft parts with exact measurements and fine details, ensuring every piece matches the desired specifications. Consistent quality output – They produce items that are exactly alike, making sure each product is as good as the last. CNC lathe machining can now be said to be a very popular processing technology. Compared with ordinary lathes, CNC lathes between the two are more likely to highlight its advantages. Let's analyze the advantages and disadvantages of these comparisons. In the dynamic world of manufacturing, a career as a CNC (Computer Numerical Control) Lathe Machinist is both rewarding and in high demand. CNC Lathe Machinists play a crucial role in the production of precision components and parts. This article will guide aspiring individuals on the best route to becoming a CNC Lathe Machinist, offering [.]

CNC lathe machines offer high precision and accuracy, making them ideal for industries that require fine tolerances. They provide versatility in working with various materials, from plastics to rigid foam, expanding the range of possibilities. CNC machines can create simulated models or prototypes, saving time and material costs.

Discover the advantages and disadvantages of using a CNC lathe machine, including precision, productivity, and potential costs involved.

CNC Lathe: These are automated lathes, often guided by computer numeric control (CNC), providing high-precision and mass production capabilities with minimal human intervention. Speed Lathe: Speed lathe machines, with their high RPM range, are optimal for woodworking, polishing, and metal spinning applications.Advantages include increased accuracy and improved safety. Disadvantages include high initial cost and limited maneuverability. Lathes are available in manual and CNC versions. Maintenance is required to ensure optimal performance. What Are the Advantages of Using a Lathe?

disadvantages of cnc lathe machine

china cnc wood router machine factories

different types of cnc lathe

• KIT INCLUDES: Pre-assembled 2-drawer metal cabinet with hardware, stainless steel sink, strainer, and fully adjustable high arc Flex+Freeze faucet • MULTI-PURPOSE: UV-resistant .

advantages and disadvantages of cnc lathe machine|disadvantages of cnc lathe machine