cross break sheet metal Learn what a cross break is in sheet metal, how to form and design it, and why it is used to strengthen parts. See how cross breaks are applied to duct work and machine enclosures. Buy precision engineered parts in bulk online from 245 verified wholesale precision engineered parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources.Precision machining is a vital part of the production of components that you likely use every day. The auto, electrical, electronics, medical, and aerospace industries all rely heavily on precisely machined parts to produce products that meet quality and safety standards. Precision machining can be used to design . See more

0 · solidworks sheet metal cross break

1 · sheet metal stiffening techniques

2 · sheet metal scoring tool

3 · sheet metal cross break tool

4 · how to stiffen sheet metal

5 · duct beading machine

6 · cross broken ductwork

7 · beading in sheet metal

Our dedicated solar energy representatives can help design, supply and assist you with your solar energy system. When you decide to go solar with us, we provide leading customer care and support to getting your system completed right, from start to finish. We offer wholesale pricing, quality manufacturers, and excellent support. Request a quote .

Learn what a cross break is in sheet metal, how to form and design it, and why it is used to strengthen parts. See how cross breaks are applied to duct work and machine enclosures. We used the following equipment to produce this video: Bar fold http://amzn.to/2ebBI4w samsung note 2 I show you how to get a cross break in sheet metal without a sheet metal break..

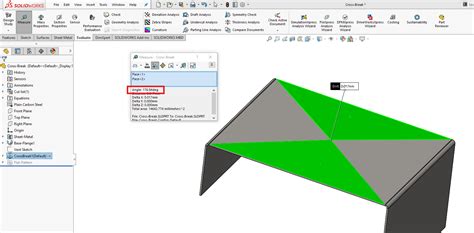

Learn how to use a forming tool to achieve a 3D cross-break effect in SOLIDWORKS sheet metal design. Follow the steps to sketch, loft, and apply a forming tool to . Learn how to stiffen and strengthen ductwork or sheet metal products using cross-braking or beading methods. Compare the advantages and disadvantages of each technique and find out which one suits your workshop's . SolidWorks II Sheet Metal II Cross Break: A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat secti.

The Cross Break command lets you insert a graphical representation of a cross break in a sheet metal part. The cross break is not a geometric entity and does not alter the geometry of the . Follow along using the transcript. 159 SolidWorks Sheet Metal Tutorial: Cross-Break, reasons to use, real examples, single and multiple faces, cross break options, editing cross-break.Click Cross Break (Sheet Metal toolbar) or Insert > Sheet Metal > Cross Break. In the PropertyManager, select: The face on which to create the cross break; The direction of the .- [Instructor] A cross break allows you to stiffen a flat surface in a sheet metal part, and it's used extensively in HVAC panels or anytime you see a big flat surface that needs a little.

The cross break command lets you insert a graphical representation of a cross break in a sheet metal part. The cross break is not a geometric entity and it does not alter the geometry of.A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat section thin metal. Cross breaks are most commonly in an X shape, forming a slight pyramid shape in the metal without overly distorting it.

We used the following equipment to produce this video: Bar fold http://amzn.to/2ebBI4w samsung note 2 I show you how to get a cross break in sheet metal without a sheet metal break.. A question we sometimes get in the SOLIDWORKS Sheet Metal course is how to insert a 3D cross-break. The functionality seems to be there in the SOLIDWORKS Cross-Break command on the Sheet Metal toolbar, but upon inspection, the . When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?”

SolidWorks II Sheet Metal II Cross Break: A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat secti.The Cross Break command lets you insert a graphical representation of a cross break in a sheet metal part. The cross break is not a geometric entity and does not alter the geometry of the part. You add it to provide the information needed to create the cross break during manufacturing.

Follow along using the transcript. 159 SolidWorks Sheet Metal Tutorial: Cross-Break, reasons to use, real examples, single and multiple faces, cross break options, editing cross-break.Click Cross Break (Sheet Metal toolbar) or Insert > Sheet Metal > Cross Break. In the PropertyManager, select: The face on which to create the cross break; The direction of the cross break; The Break Radius; The Break Angle; Click .- [Instructor] A cross break allows you to stiffen a flat surface in a sheet metal part, and it's used extensively in HVAC panels or anytime you see a big flat surface that needs a little.

solidworks sheet metal cross break

The cross break command lets you insert a graphical representation of a cross break in a sheet metal part. The cross break is not a geometric entity and it does not alter the geometry of.A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat section thin metal. Cross breaks are most commonly in an X shape, forming a slight pyramid shape in the metal without overly distorting it.

metal bracket site hobbylobby.com

We used the following equipment to produce this video: Bar fold http://amzn.to/2ebBI4w samsung note 2 I show you how to get a cross break in sheet metal without a sheet metal break.. A question we sometimes get in the SOLIDWORKS Sheet Metal course is how to insert a 3D cross-break. The functionality seems to be there in the SOLIDWORKS Cross-Break command on the Sheet Metal toolbar, but upon inspection, the .

When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?” SolidWorks II Sheet Metal II Cross Break: A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat secti.The Cross Break command lets you insert a graphical representation of a cross break in a sheet metal part. The cross break is not a geometric entity and does not alter the geometry of the part. You add it to provide the information needed to create the cross break during manufacturing. Follow along using the transcript. 159 SolidWorks Sheet Metal Tutorial: Cross-Break, reasons to use, real examples, single and multiple faces, cross break options, editing cross-break.

Click Cross Break (Sheet Metal toolbar) or Insert > Sheet Metal > Cross Break. In the PropertyManager, select: The face on which to create the cross break; The direction of the cross break; The Break Radius; The Break Angle; Click .- [Instructor] A cross break allows you to stiffen a flat surface in a sheet metal part, and it's used extensively in HVAC panels or anytime you see a big flat surface that needs a little.

sheet metal stiffening techniques

sheet metal scoring tool

Fathom delivers high-quality parts to its customers by using sheet metal fabrication technology. Whether your project is time-sensitive, high-precision, highly complex or short production run related, Fathom will meet your requirements.

cross break sheet metal|cross broken ductwork