sealing junction boxes behind drywall The NEC 314.29 prohibits covering up boxes such that you'd need to remove . I was wondering if every metal receptacle need to be grounded via a green ground screw screwed in a hole in the back and connected to the other ground wires coming into and .

0 · splicing wire inside wall

1 · splicing electrical wires behind walls

2 · in wall splice kit legal

3 · hidden junction box in wall

4 · extending romex behind drywall

5 · drywall patch over electrical box

6 · are junction boxes legal

7 · approved in wall wire splice

Considering the NEC guidelines, it is generally not recommended to place a junction box inside a wall. This is primarily because accessibility can be compromised if the junction box is hidden within the wall cavity.

The "best way" is to replace all the damaged wire. Either completely (from where it starts and ends now) or by adding two junction boxes (which must remain accessible) where you can join the undamaged parts of the wire to new undamaged wire between the two junction .The NEC 314.29 prohibits covering up boxes such that you'd need to remove .Seal around installed wiring using caulk or canned spray foam. For ceiling-mounted electrical boxes, install the electrical box in the ceiling drywall, then caulk around the base and caulk all .You cannot cover any junction box that still has live wires in it. Your best bet is to either remove the box all together or just put a cover plate on it. Your other option is to run a new circuit to .

If you have any boxes you can access from behind, you can use the orange fire stop spray foam. There is also a product out there that is sold as small square sheets of reddish clay-like material. It’s a putty that can be . The NEC 314.29 prohibits covering up boxes such that you'd need to remove "part of the building" to access the wires inside. The drywall is considered "part of the building." You . Once the drywall has been installed, the Box Shell can be filled with expanding latex foam. The foam seals the electrical box and insulates the space behind the box. Two architects have come up with an inexpensive way of air . It is illegal to put drywall over an electrical outlet or junction box with electrical wires connected or terminated inside the box. If the electrical outlet box is empty or the wire runs through it without terminating, you can cover it .

Do not cover junction box covers with drywall or other surface material – they are necessary for proper wiring and installation. Always make sure that your junction box covers are accessible so you don’t have to go digging . If 'it'* has a removable cover and contains any circuit conductors it must not be covered by drywall or and finish. *conduit bodies, other fittings, boxes, wireways etc.

splicing wire inside wall

Junction boxes must be grounded to provide a path for fault current to return to the source and to prevent electrical shock. Using an approved grounding method, you must connect the grounding conductor to the junction .Junction box placement on wall ovens is varied, depends on what is already there, and what fits where regarding the new appliance. So yes, sometimes they go behind the oven. Plan carefully with measurements regarding the full logistics of getting the oven in/out of . Under the electrical/phone box on exterior walls section, the code states: The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed. The code gives two . Junction boxes (also known as electrical boxes, switch boxes, ceiling boxes, etc.) are designed to be a safe place for connections—junctions—between wires to take place. That way if you have a .

Figure 2. Air-sealing an electrical box (Source: Air Barriers - Airtight Drywall Approach, Info-401 2009). Another option is to install standard electrical boxes and seal all openings in the box (including around wire penetrations) with caulk or sealing putty, then seal the face of the box to the drywall with caulk (Figure 3). Covering your junction boxes with drywall may result in less access for technicians when repairs or changes need to be made, so be aware of this potential downside before making a decision. . Dead or live electrical wires should never be buried behind drywall. This is a dangerous and potentially life-threatening mistake.

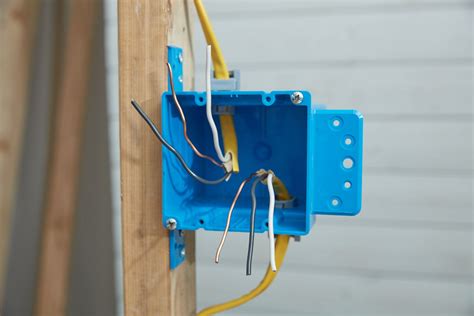

Don’t drill the box. It appears to have three available corner tabs that can be bent back to use. Don’t mount a box to this box. Don’t surface mount a box. An old work box will probably be dropped into a correctly sized hole in the drywall in the same stud bay on the other side.I opened up the walls in my bathroom to replace the shower and found this junction box in the wall. I know it's a no-no to hide a junction box, but to make it better this is next to the shower mixing valve. The circuit is for the dryer. Apparently when a previous owner moved the laundry they left this gem for me. From that side, I pulled the wires from the old outlet box, pried the box off the stud, and then installed a metal junction box facing the garage. Fed the wires in through a strain relief, wirenutted the hots, the neutrals, and screwed the ground to the box. Then I drywall over the old hole in the kitchen.

When you bury the electrical junction inside or behind a wall, it remains hidden from view, resulting in unseen occurrences due to the lack of visibility inside the box. Can a junction box be hidden behind drywall? As per the United States electrical code, it has been mentioned that it should never be attempted to keep a junction box behind .I’m going to get burned here but why is it really bad to have a junction box behind the sheetrock? We are redoing our kitchen and found super shady electrical work and we have to install three junction boxes. Option 1 is to have a plate visible in the kitchen ceiling so they are accessible or Option 2 is hide them behind the sheetrock.If these rooms are internal to the main house and you are re-adding drywall to the studs, then airsealing isn't necessary. In this case I would be more interested in adding sound-deadening insulation like mineral wool. Edit: if you're dead-set on airsealing, just caulk the cracks behind the box with something decent.

Installing a new light fixture in a finished bathroom. The junction box was mounted too deep, behind the drywall. The only way I can get the new light mounted flush to the ceiling, and get the cap nuts on is to mount the new fixtures mounting bar .Option 3: duct seal putty. Seal the box's perimeter. If there's plaster around it, it might not be attached well. If so, remove it. Make a big enough gap around the box for caulk. Then, caulk. With access behind the wall: Use putty pads. I would still caulk the perimeter and holes first. Ideally use a box that's better for sealing.

splicing electrical wires behind walls

If any new wires need to be pulled in the future and there are other hidden junction boxes in the wall, say goodbye to a lot of drywall, and hello to re-doing said drywall and re-painting, plus all the expenses. . I have a junction box like this, but its buried behind cabinets. It powers the fridge. It's not buried, but it isn't somewhere .

Ok, so I guess this isn't a big deal like I thought it might be; it just looked odd to see an electrical box behind a shower wall. . .but of course this is the first shower wall that I have ever opened up. Old Dog, you are correct, the horizontal wire is going to a box in the bathroom; it is an outlet that is just outside of the photo.

It’s a putty that can be squished around a box from behind to seal the box and wall. The material is commonly used in fire rated wall assemblies and for soundproofing. The number one rule is to keep the material you use from .Vapor Seal Series Features & Benefits (A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier.Flange products “V” are for single drywall and “V2” are for double drywall applications .Hi there. I'm replacing the built-in double wall oven in my home and the junction box is in the wrong spot. It's currently positioned in the upper middle of the space behind the oven and it needs to be positioned at the top right corner of the space. Last week a friend put a screw through a wall and straight into a wire. They called out an electrician who cut a small square of the dry wall away and added the splice pictured below. I was surprised when he told me the electrician said he could go ahead and fix the dry wall to fill the hole now.

An older but labor intensive sealing technique that still works is to put a 12″x12″ piece of 6-mil poly behind the box prior to mounting it to the wall, and wrap the box with the poly. Wherever a wire goes through the poly wrap, apply Tremco acoustical sealant (“black death”) around the wire at penetration.

You are correct, the junction boxes must remain accessible. The NEC 314.29 prohibits covering up boxes such that you'd need to remove "part of the building" to access the wires inside. If the box is secure, it's OK. I'd get some mortar to seal in the box. It will secure the box even more. Where the openings are real small, use some silicone caulk. Adding insulation at this point would be a big job. There's a possibility just that one area lacks it because of the box and sealing around the box will help.I'd like to move the box inside and replace the light fixture. My question is do I just cut a circular hole in the wall and mount a normal junction box inside? Or do I need a weather-proof junction box? I will be using a wet-rated light fixture. The arrowed light fixture is the one I'm referring too. The other painted one isn't functional.

While replacing my bathroom vanity lights I found that the old junction box doesn't sit flush with the wall and with my new vanity it is an issue. I tried getting a 'old work' junction box that latches on to the drywall but the hole is a little too big for the junction box to sit flush.The new light fixture had a really thin foam gasket, but it was pretty much pointless since the bracket that held the fixture to the junction box didn't actually hug the fixture to the wall to create any seal. Is there a trick to getting the junction box sealed, or the fixture sealed to .

Just wondering if I need to pull out and replace an old plastic electrical wall box that sits a good 3/4" behind the drywall? Seems like you would want a tight fit for heat sealing, but is there an electrical code reason? Box has three 10-2 romex cables with grounds for a 240v thermostat. It is on an interior wall. In retrospect, I probably should have bought a junction box that has a hole in the back and put it directly over where the wire comes out of the wall. I noticed that some have caps that can seal unneeded holes but not the model I bought.

in wall splice kit legal

hidden junction box in wall

Wholesale Sheet Metal has been a trustworthy and reliable source of heating, ventilating, air conditioning and sheet metal products in our market for over 35 years. Our courteous and professional staff with unparalleled service has made us an industry leader.

sealing junction boxes behind drywall|hidden junction box in wall