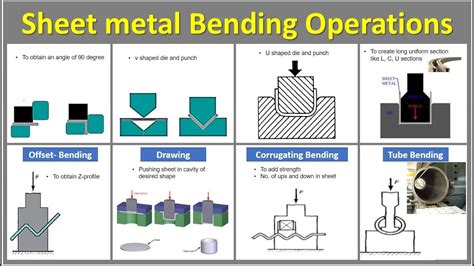

sheet metal folding and bending Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is . JACK’S METAL WORKS is Boise’s premier metal fabrication company. We specialize in creating custom projects, retail metal sales, item repair and all your other metal needs. With our large stock of ready to purchase metal & industry standard equipment, we can handle any job, big or .

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Welding and Metal Fabrication by Larry Jeffus. Table of Contents: 1. Introduction. 2. Safety. 3. Shop Math. 4. Reading Technical Drawings. 5. Welding Joint Design, Welding Symbols. 6. Fabricating Techniques and Practices. 7. Welding Shop Practices. 8. Shielded Metal Arc Equipment, Setup, and Operation. 9. Shielded Metal Arc Welding Plate. 10 .Larry Jeffus Solutions. Below are Chegg supported textbooks by Larry Jeffus. Select a textbook to see worked-out Solutions.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .The next generation of folding technology and innovation. Developed over the course of several years, our work is guaranteed by our unrivaled quality and flexibility in bending. . However, this can permanently damage your sheet .

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is .

12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand Seamer, . Metal Forming Tool for Duct Work & Metal Roofing; Premier Sheet Metal Folding Bar & Bending Tool for Professionals. Share: Found a lower price? Let us know. Although we can't match every price reported, we'll use your feedback to ensure that our prices remain .Sheet metal folding is bending a metal sheet to create specific angles and shapes. It involves applying force to the metal to change its geometry without altering its volume. This technique is widely used in manufacturing to create parts with accurate and consistent dimensions. Metal Bending : Our sheet metal folding is designed to effortlessly and precisely bend metal into the desired shapes, the folded seam is formed by permanently joining two half-steels. Two Folding Depths: This bending offers 3/8" and 1" folding depths, catering to various requirements in handling seams, edges, flat bottoms, or driving edges in .

Folding Tool Steel Metal Bending Tool Sheet Metal Bender for HVAC Metal Bending Forming 3/8" and 1" Fold Depths in Ductwork (24 Inch) 4.9 out of 5 stars 16. .05 $ 67. 05. .93 delivery Tue, Oct 1 . Seller rating: 4.9/5 (15) Add to cart-Remove. More buying choices .86 (3 .

HURRICANE 12 Inch Folding Tool, Sheet Metal Bending Tools for HVAC, Duct Bender Hand Tool, Forming Metal. 4.5 out of 5 stars. 713. 100+ bought in past month. .99 $ 17. 99. 10% off coupon applied Save 10% with coupon. FREE delivery Sun, Oct 27 on of items shipped by Amazon. Or fastest delivery Wed, Oct 23 .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .CNC sheet metal bending offers precision, consistency, versatility, and cost-effective formed metal parts. Bending and folding is one of the most common sheet metal fabrication processes. This method is used to manipulate sheet metal into an angular shape or form using a press brake.

Step By Step Guide to Sheet Metal Bending and Folding. There are 4 steps involved in a successful metal bending-Step 1: Initial Design. It is the foremost step in performing metal bending. Certain factors need to be considered while planning an initial design for bending a metal sheet. These factors are bending deduction, flange length, bend . 【Sheet Metal Folding Tool】Hurricane 12" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from 2 steel halves, permanently joined together. 【Two Folding Depths】Creates 3/8" and 1" .Whether it’s a one-off item or large production runs North Harbour Engineering offers precision sheet metal folding and bending services. Using our Baykel 3100 x 160 ton CNC, we are able to fold up to 5mm mild steel plate in lengths up to 3 meters. . Precision sheet metal folding services. Using our state-of-the-art CNC machine, we are able .HURRICANE 18 Inch Folding Tool, Sheet Metal Bending Tool for HVAC, Bending and Forming Metal. 4.5 out of 5 stars. 689. 200+ bought in past month. .99 $ 23. 99. FREE delivery Sun, Aug 25 on of items shipped by Amazon. Or fastest delivery Wed, Aug 21 .

types of bending sheet metal

WHAT IS METAL FOLDING? Metal folding is a process used to fold or form sheet metal into a desired shape. A press brake is used to bend or fold the metal by lowering a punch that has been positioned on top of a die. The metal may be bent several times by a press brake until the desired form has been achieved.

sheet metal bending standards

Torsion Bar Nc Press Brake Plate Bending Machine Sheet Metal Folding Factory Price US,300.00-23,700.00 1 piece (MOQ) Three Station Roller for Bending Metal, 90 Degrees Bending 0.3‑1.0mm Folding 13‑130mm, Aluminum Alloy Sheet Metal Bender, for Bending Metal Roofing Materials. 2 offers from 379 $ 103 79. . The item is a 3 station edge roller bender roofing sheet metal bending tool. It is used to bend metal plates within the range of 0-90 degrees with a .Sheet Metal Folding Tool: Hurricane 18" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together Two Folding Depths: Creates 3/8" and 1" . Press-bending is a key step in metal sheet manufacture. However, DIY approaches are often used and those highly limit the potential of machines and operators. In this guide, press-bending is discussed in all its aspects with an extremely practical approach. The work experiences of the author, as well as his experience as a teacher at the .

Malco’s 12F, 18F, and 24F Sheet Metal Folding Tools offer a premium choice for bending and forming metal. Each model is made with superior design and includes handy sight holes to ensure proper depth alignment. Whether you are an HVAC or roofing pro, Malco offers you the right tool to get the job done.

Understanding the differences between sheet metal bending and folding is crucial for selecting the right technique for your project. Whether you need precise, simple bends or complex, multi-dimensional folds, both processes offer unique advantages that can enhance the functionality and aesthetics of your metal components, each offering distinct advantages for .3706.02 Bending and Springback in the Folding Process The Bending Process Folding consists of three bending operations: down-flanging to 90°, bending from 90° to 135° and finally finishing from 135° to 180°. In the standard down-flanging operation the part is clamped on one side. The punch moves downward (or upward) forming the

5 things to consider when looking at metal folding machines. Metal folding machines are available in many different configurations and offer the ability to fold different components with little, or no tool change required. To ensure you choose the correct folder for your application you must consider the following:. What is the maximum bending length required?

Three sizes of sheet metal bending pliers for your selection: straight jaw, 45 degree jaw, 90 degree jaw. These hand seamers are 2-3/8'' (60mm) wide. Designed for bending or straightening sheet metal edge. Ideal tool for use on the car when it is not possible to use a bench folding machine or in tight areas.We offer precision sheet metal bending and folding for quality part production. Brampton Sheetmetal is your one stop shop for sheet metal folding in Melbourne. We use cutting-edge industry technology to produce components folded accurately, every time. Our brake press machinery achieves reliably precise results for parts orders of any size. First bend to form an L bending and then further processed to form a Z bending (if interfere with machine worktable, first bend 1 to form a large angle, then bend 2 and then press 1); Using two acute angles to form Z bending: first bend into a .

Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the bend.. The basic principle of the . A comparative review of Metal Folding and Bending from Omnidex Laser. A comparative review of Metal Folding and Bending. Introduction. In metal fabrication, metal folding; the transformation of flat material sheets into 3D structures has gained a lot of popularity in recent years.Sheet Metal Bending and metal folding have emerged as essential manufacturing .

electric lunch box for sale

electric lunch box stove

sheet metal bending near me

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

sheet metal folding and bending|sheet metal bending near me