cnc machine movement Almost all CNC machines can have programmable motion types (whether fast, linear or circular), amount of motion, feedback rate and axis to move. Motion control is a relatively simple function in any CNC machine. Before I started my riveting I built a watertight metal box and then practiced putting rivets into the bottom to test out how well sealed they were (I fill the box with water and then .

0 · what is a cnc machine

1 · types of cnc movements

2 · example of a cnc motion

3 · cnc rotating centers

4 · cnc motion types

5 · cnc motion software

6 · cnc machine motion control

7 · cnc control movement

All tanks (both underground and above ground), piping and fittings, foot valves, leak detectors, cor-rosion protection devices, wiring, venting systems, etc., must be installed in accordance with the manufacturer’s instructions and in compliance with local and regional building codes and require-ments pertaining to service stations (or other loc.

CNCMotion integrates interactive 3D simulation with CNCBase machine control software for dynamic simulation and graphic tracking of Intelitek’s CNC mills and lathes. Almost all CNC machines can have programmable motion types (whether fast, linear or circular), amount of motion, feedback rate and axis to move. Motion control is a relatively simple function in any CNC machine. Motion control is a logical step in improving the quality and consistency of CNC machining. These motions may seem complicated, but the right know-how will improve CNC-based production outputs. Reliable .

The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and .

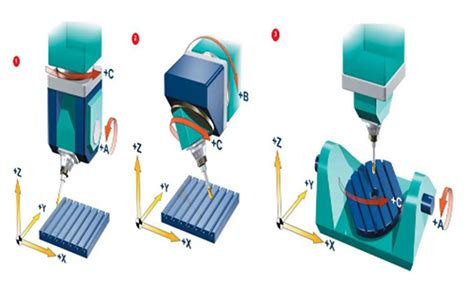

CNC movements are based on the X, Y and Z axes. The tool is positioned using stepper or servo motors, which act on the movements based on the code obtained from the original 3D model of the part you want to create – .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).In CNC, the machine needs to move the tool between two points. The computer calculates all of the measurements between the two points. This calculation is approximately the idea of “adding something in between the two points.” The .

Machining Transformation (MX) marks the transition to networked, digitized and sustainable CNC manufacturing. At the heart of this revolution are the four core areas of Process Integration, Automation, Digital Transformation .In Computerized Numerical Control (CNC) machining, the part is on the table. Sometimes the table moves under the quill. Sometimes, the table is fixed and the quill moves. The quill is another name for spindle. The quill holds the cutter. . While your particular CNC machine may have more motion types (depending on your application), let's concentrate on the three most common types available on almost all forms of CNC equipment. After briefly introducing each type of motion, we'll show an example program that stresses the use of all three.CNCMotion integrates interactive 3D simulation with CNCBase machine control software for dynamic simulation and graphic tracking of Intelitek’s CNC mills and lathes.

Almost all CNC machines can have programmable motion types (whether fast, linear or circular), amount of motion, feedback rate and axis to move. Motion control is a relatively simple function in any CNC machine.

what is a cnc machine

Motion control is a logical step in improving the quality and consistency of CNC machining. These motions may seem complicated, but the right know-how will improve CNC-based production outputs. Reliable engineers can only do so much in a set period. The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and automatically positioned along their lengths of travel.

types of sheets in sheet metal

CNC movements are based on the X, Y and Z axes. The tool is positioned using stepper or servo motors, which act on the movements based on the code obtained from the original 3D model of the part you want to create – called the G-code.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).In CNC, the machine needs to move the tool between two points. The computer calculates all of the measurements between the two points. This calculation is approximately the idea of “adding something in between the two points.” The word interpolation is trying to explain the computer calculations to make the machine tool move from point to point.

Machining Transformation (MX) marks the transition to networked, digitized and sustainable CNC manufacturing. At the heart of this revolution are the four core areas of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX).In Computerized Numerical Control (CNC) machining, the part is on the table. Sometimes the table moves under the quill. Sometimes, the table is fixed and the quill moves. The quill is another name for spindle. The quill holds the cutter. When we talk of machine movement we will talk as if the table is fixed and the quill is moving. While your particular CNC machine may have more motion types (depending on your application), let's concentrate on the three most common types available on almost all forms of CNC equipment. After briefly introducing each type of motion, we'll show an example program that stresses the use of all three.

types of cnc movements

CNCMotion integrates interactive 3D simulation with CNCBase machine control software for dynamic simulation and graphic tracking of Intelitek’s CNC mills and lathes. Almost all CNC machines can have programmable motion types (whether fast, linear or circular), amount of motion, feedback rate and axis to move. Motion control is a relatively simple function in any CNC machine.

Motion control is a logical step in improving the quality and consistency of CNC machining. These motions may seem complicated, but the right know-how will improve CNC-based production outputs. Reliable engineers can only do so much in a set period. The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and automatically positioned along their lengths of travel.

CNC movements are based on the X, Y and Z axes. The tool is positioned using stepper or servo motors, which act on the movements based on the code obtained from the original 3D model of the part you want to create – called the G-code.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).In CNC, the machine needs to move the tool between two points. The computer calculates all of the measurements between the two points. This calculation is approximately the idea of “adding something in between the two points.” The word interpolation is trying to explain the computer calculations to make the machine tool move from point to point.

Machining Transformation (MX) marks the transition to networked, digitized and sustainable CNC manufacturing. At the heart of this revolution are the four core areas of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX).

example of a cnc motion

types of metal angle brackets

tyco approved concealed junction box

$22.17

cnc machine movement|cnc motion types