anodic aluminum oxide fabrication Fabrication of a Silica–Silica Nanoparticle Monolayer Array Nanocomposite Film on an Anodic Aluminum Oxide Substrate and Its Optical and Tribological Properties. ACS Applied Materials & Interfaces 2020 , 12 (24) , . Lighting, Light Fixtures, Ceiling and Exhaust Fans - Outdoor Lighting Box Size - I will be installing some sconce lights in a CMU block wall, but I don't know what size junction box I should install. I don't know what fixture I'm going to use yet, so I need to install the junction box now and pick the ficture later. Is

0 · nano aluminium oxide

1 · anodizing sem

2 · anodized aluminum wiki

3 · anodic oxide film

4 · anodic aluminum oxide template

5 · anodic aluminum oxide membrane

6 · aluminum oxide nanoparticles applications

7 · aao masuda and fukuda

CNC (Computer Numerical Control) machines rely on specialized software to control and automate their operations. This software acts as the brain behind the intricate movements and actions of CNC machines. By utilizing a combination of hardware and software, CNC machines can precisely fabricate door hardware components with unmatched accuracy.From appliances and light fixtures to desk tools, chairs, and utensils, metal is the stabilizing element that makes all of today’s .

nano aluminium oxide

In this review, we focus on various fabrication methods, pore geometry modification, and recent advances of AAO, as well as sensor applications linked to our environment, daily life, and safety. Fabrication of a Silica–Silica Nanoparticle Monolayer Array Nanocomposite Film on an Anodic Aluminum Oxide Substrate and Its Optical and Tribological Properties. ACS Applied Materials & Interfaces 2020 , 12 (24) , .

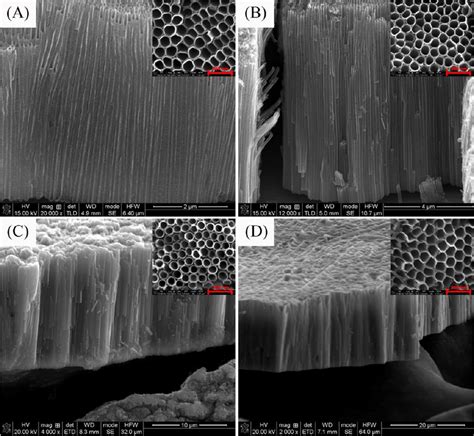

Anodic aluminum oxide (AAO) consists of parallel pores arranged in a honeycomb-like array. Since a two-step self-organized approach in anodic alumina fabrication was .

what is distribution code 1 in box 7 of 1099-r

Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore . Due to the unique optical and electrochemical properties, large surface area, tunable properties, and high thermal stability, nanoporous anodic aluminum oxide (AAO) has . Porous anodic aluminum oxide (AAO) is one of the most typical ordered porous structures and can be easily fabricated by applying an electrochemical anodizing process to Al. The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and .

Material fabrication of AAO is based on facile and inexpensive electrochemical anodization with the self-ordering process of nanopores not requiring any lithography or .Anodic aluminum oxide, anodic aluminum oxide (AAO), or anodic alumina is a self-organized form of aluminum oxide that has a honeycomb -like structure formed by high density arrays of .

Creating a porous black surface on aluminium alloy in a controllable fashion. The resulting coating achieves high thermal emittance (0.96), high solar absorptivity (0.921) and . In this review, we focus on various fabrication methods, pore geometry modification, and recent advances of AAO, as well as sensor applications linked to our environment, daily life, and safety.

Fabrication of a Silica–Silica Nanoparticle Monolayer Array Nanocomposite Film on an Anodic Aluminum Oxide Substrate and Its Optical and Tribological Properties. ACS Applied Materials & Interfaces 2020 , 12 (24) , 27672-27681. Anodic aluminum oxide (AAO) consists of parallel pores arranged in a honeycomb-like array. Since a two-step self-organized approach in anodic alumina fabrication was invented, tremendous attention was paid to this material. Structural features of anodic alumina, like. Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore combinations. Due to the unique optical and electrochemical properties, large surface area, tunable properties, and high thermal stability, nanoporous anodic aluminum oxide (AAO) has become one of the most.

Porous anodic aluminum oxide (AAO) is one of the most typical ordered porous structures and can be easily fabricated by applying an electrochemical anodizing process to Al. The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and good thermal stability. Moreover, the AAO template serves as a valuable tool for creating anodic aluminum oxide.

Material fabrication of AAO is based on facile and inexpensive electrochemical anodization with the self-ordering process of nanopores not requiring any lithography or templating, and the outcome of the process are perfectly ordered and size controlled nanopores with distinctive pore geometries.

Anodic aluminum oxide, anodic aluminum oxide (AAO), or anodic alumina is a self-organized form of aluminum oxide that has a honeycomb -like structure formed by high density arrays of uniform and parallel pores.

Creating a porous black surface on aluminium alloy in a controllable fashion. The resulting coating achieves high thermal emittance (0.96), high solar absorptivity (0.921) and unique UV resistance. A unique anti-icing feature can be realised by effectively delaying the frozen of water droplet. In this review, we focus on various fabrication methods, pore geometry modification, and recent advances of AAO, as well as sensor applications linked to our environment, daily life, and safety. Fabrication of a Silica–Silica Nanoparticle Monolayer Array Nanocomposite Film on an Anodic Aluminum Oxide Substrate and Its Optical and Tribological Properties. ACS Applied Materials & Interfaces 2020 , 12 (24) , 27672-27681. Anodic aluminum oxide (AAO) consists of parallel pores arranged in a honeycomb-like array. Since a two-step self-organized approach in anodic alumina fabrication was invented, tremendous attention was paid to this material. Structural features of anodic alumina, like.

Here the authors report fabrication of designable anodic aluminum oxide templates with controllable in-plane and out-of-plane shapes, sizes, spatial configurations, and pore combinations. Due to the unique optical and electrochemical properties, large surface area, tunable properties, and high thermal stability, nanoporous anodic aluminum oxide (AAO) has become one of the most. Porous anodic aluminum oxide (AAO) is one of the most typical ordered porous structures and can be easily fabricated by applying an electrochemical anodizing process to Al.

The anodic aluminum oxide (AAO) template is the perfect mold because it offers many desired qualities, such as adjustable pore diameters, high mechanical properties, and good thermal stability. Moreover, the AAO template serves as a valuable tool for creating anodic aluminum oxide. Material fabrication of AAO is based on facile and inexpensive electrochemical anodization with the self-ordering process of nanopores not requiring any lithography or templating, and the outcome of the process are perfectly ordered and size controlled nanopores with distinctive pore geometries.

Anodic aluminum oxide, anodic aluminum oxide (AAO), or anodic alumina is a self-organized form of aluminum oxide that has a honeycomb -like structure formed by high density arrays of uniform and parallel pores.

what is coining in sheet metal

$37.24

anodic aluminum oxide fabrication|aao masuda and fukuda