design for sheet metal forming * source: http://www.cyrilbath.com/sheet_process.html See more CNC machines and machine centers are a type of computer-programmable equipment that needs instructions to dictate their movement and functions. The machine operator gives these instructions to the machine in the form of G .

0 · sheet metal layout drawings

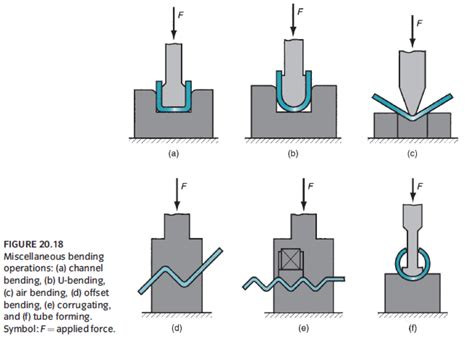

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

Dry Cycle Testing Once everything else is complete, a final test of the system is needed to make sure all of the different components can work together in harmony. This ‘dry .

sheet metal layout drawings

cnc shearing machine price

Low volume batches Hydro-forming – cheap tooling, no net thinning, slow(ish), high formability Low volume batches See moren eff assuming perfectly plastic, yielding at: σ = Y eff See more* source: http://www.cyrilbath.com/sheet_process.html See moreAt Y, material defoms (‘flows’) in compression and fails in tension Interested in elastic and plastic effects: See more

Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .

Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.From a first principles perspective, sheet metal design for manufacturability is based entirely on the design engineer’s understanding of how desired features and feature tolerances are impacted by the range of anticipated forming . Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling metal into different shapes and .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges ObjectivesSheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run times on small lots and prototypes.

sheet metal forming types

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.From a first principles perspective, sheet metal design for manufacturability is based entirely on the design engineer’s understanding of how desired features and feature tolerances are impacted by the range of anticipated forming operations. Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling metal into different shapes and structures. The first step in creating a sheet metal part is sheet metal design. Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.

Successful sheet-metal forming depends on the selection of a material with adequate formability, the proper design of the part and the tooling, the surface condition of the sheet, the selection and application of lubricants, and the speed of the forming press.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges ObjectivesSheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run times on small lots and prototypes. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

From a first principles perspective, sheet metal design for manufacturability is based entirely on the design engineer’s understanding of how desired features and feature tolerances are impacted by the range of anticipated forming operations. Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling metal into different shapes and structures. The first step in creating a sheet metal part is sheet metal design.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments. Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.Successful sheet-metal forming depends on the selection of a material with adequate formability, the proper design of the part and the tooling, the surface condition of the sheet, the selection and application of lubricants, and the speed of the forming press.

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding.

design for sheet metal forming|forming process in sheet metal