cnc machine arm FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: From collaborative robots to robotic arms, our solutions are designed to . As far as I can tell plastic boxes are an inferior box once installed, but plastic are easier/faster to install than metal. For example plastic boxes often have built in nails and romex clamps, while metal boxes lack both. And metal boxes can be .

0 · single arm cnc plasma cutter

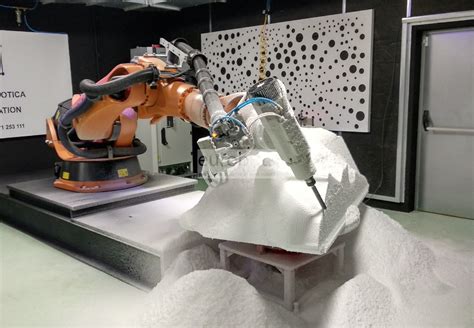

1 · robotic arm milling machine

2 · robotic arm cnc milling

3 · plasma cutter robot arm

4 · cnc robotic arm price

5 · cnc robotic arm

6 · cnc plasma cutting arm

7 · automatic loading and unloading robot

You can use metal and romex, sometimes it is preferable and even necessary to use metal. Larger switch boxes for instance. Plastic has its place and it gets the job done just fine.

Looking for the best CNC robot arm to automate your CNC machining? We’ve got you covered with the best 3 on the market.

When choosing a CNC Milling robot, consider the types of parts you produce, .FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: From collaborative robots to robotic arms, our solutions are designed to .

HALTER CNC Automation has developed the HALTER LoadAssistants, based on its many years of experience in the machining industry and production automation: the Basic Pro, the all-in-one Universal (for turning and milling), the .A CNC robot, also known as a CNC machine tending robot, is designed to interact with CNC machines. These robots are typically articulated arms programmed to load and unload .

When choosing a CNC Milling robot, consider the types of parts you produce, your shop's needs, and available floor space. Articulated arm robots are very flexible but require more space, while gantry-style robots save space but are .Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.Halter has advanced the field of CNC automation and developed a loading robotic arm, easily connected to any CNC machine. The TurnStacker Series are robotic loading solutions designed specifically for your CNC turning machines.Looking for the best CNC robot arm to automate your CNC machining? We’ve got you covered with the best 3 on the market.

FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: From collaborative robots to robotic arms, our solutions are designed to help you get the most out of your machines by automating them with little to no down time.

Although efficient work is complex, the DOBOT CR robot arm with AGV can feed multiple CNC machines, effectively reducing labor costs and avoiding large-scale re-engineering of automated lines. It is a safe solution for lightweight production.HALTER CNC Automation has developed the HALTER LoadAssistants, based on its many years of experience in the machining industry and production automation: the Basic Pro, the all-in-one Universal (for turning and milling), the TurnStacker and the MillStacker.A CNC robot, also known as a CNC machine tending robot, is designed to interact with CNC machines. These robots are typically articulated arms programmed to load and unload materials, and can perform post-machining tasks.

When choosing a CNC Milling robot, consider the types of parts you produce, your shop's needs, and available floor space. Articulated arm robots are very flexible but require more space, while gantry-style robots save space but are less dexterous and adaptable.

Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.Halter has advanced the field of CNC automation and developed a loading robotic arm, easily connected to any CNC machine. The TurnStacker Series are robotic loading solutions designed specifically for your CNC turning machines. Machine tending robot arms enhance production efficiency by automating the loading and unloading of CNC machines or Lathe machines, facilitating 24/7 operations without constant human oversight. Welding robot arms are used in sectors demanding high-strength, precision welds such as aerospace and automotive manufacturing.The deployment of the CNC robotic arm to tend CNC machines in new processes is fast and easy, giving you the agility to automate almost any manual task, including those with small batches or fast change-overs.

Looking for the best CNC robot arm to automate your CNC machining? We’ve got you covered with the best 3 on the market.FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: From collaborative robots to robotic arms, our solutions are designed to help you get the most out of your machines by automating them with little to no down time. Although efficient work is complex, the DOBOT CR robot arm with AGV can feed multiple CNC machines, effectively reducing labor costs and avoiding large-scale re-engineering of automated lines. It is a safe solution for lightweight production.

cnc machining syracuse

HALTER CNC Automation has developed the HALTER LoadAssistants, based on its many years of experience in the machining industry and production automation: the Basic Pro, the all-in-one Universal (for turning and milling), the TurnStacker and the MillStacker.A CNC robot, also known as a CNC machine tending robot, is designed to interact with CNC machines. These robots are typically articulated arms programmed to load and unload materials, and can perform post-machining tasks.When choosing a CNC Milling robot, consider the types of parts you produce, your shop's needs, and available floor space. Articulated arm robots are very flexible but require more space, while gantry-style robots save space but are less dexterous and adaptable.Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.

Halter has advanced the field of CNC automation and developed a loading robotic arm, easily connected to any CNC machine. The TurnStacker Series are robotic loading solutions designed specifically for your CNC turning machines. Machine tending robot arms enhance production efficiency by automating the loading and unloading of CNC machines or Lathe machines, facilitating 24/7 operations without constant human oversight. Welding robot arms are used in sectors demanding high-strength, precision welds such as aerospace and automotive manufacturing.

single arm cnc plasma cutter

Never Cut the Ground Wire Off: Make sure to never cut the ground wire off. When you don’t have a ground, having the line side on a gfci plug and then the rest of the circuit on the load side gives you adequate fault protection for the circuit.

cnc machine arm|single arm cnc plasma cutter