18 gauge sheet metal durability Superior Strength: Despite its relatively thin profile, 18 gauge cold rolled sheet metal offers excellent strength and durability. It can withstand heavy loads and resist bending or warping, .

A box plot, also known as a box-and-whisker plot, is a graphical representation of the distribution of a dataset. It summarizes key statistics such as the median, quartiles, and outliers, providing insights into the spread and central tendency of the data.

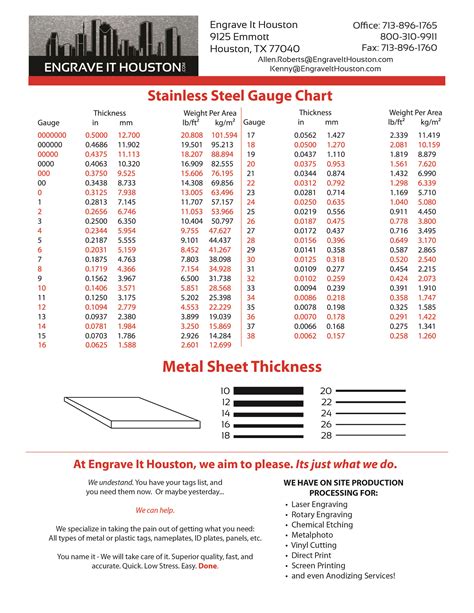

0 · sheet metal gauge chart

1 · metal plate gauge thickness chart

2 · 18ga sheet metal near me

3 · 18 gauge to fraction

4 · 18 gauge sheet metal thickness

5 · 18 gauge sheet metal near me

6 · 18 gauge galvanized steel sheet

7 · 18 gauge galvanized sheet metal

$32.96

As a DIY enthusiast, I’ve always been fascinated by the versatility of 18 gauge sheet metal. From home renovations to crafting projects, this durable and malleable material has endless possibilities. But what exactly is 18 gauge sheet metal? And how can it be used in various .Learn about 18 gauge sheet metal, its thickness, and applications in automotive, appliances, and HVAC systems. With a balanced thickness of approximately 0.048 inches, 18 gauge metal . With its optimal thickness and exceptional strength, 18 gauge sheet metal offers a wide range of applications across various industries. From automotive parts to HVAC systems, this high-quality material provides . 18 gauge stainless steel is approximately 0.05 inches or 1.27 millimeters thick. This specific thickness balances durability with workability. In the realm of metals and construction, thickness holds significant sway over a .

18 gauge 304 stainless steel offers affordability, durability, and corrosion resistance. It gets favoured for double-bowl kitchen sinks, electrical uses, and craft & model making. How thick is 18 gauge sheet metal? 18 ga thickness .Superior Strength: Despite its relatively thin profile, 18 gauge cold rolled sheet metal offers excellent strength and durability. It can withstand heavy loads and resist bending or warping, .

18-Gauge: Considered a standard thickness for auto body repair, 18-gauge sheet metal provides a balance of strength, durability, and workability. It is commonly used for patch panels, door skins, and other structural components. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material.

sheet metal gauge chart

Learn about the differences between 16 gauge and 18 gauge in carpentry, including strength, durability, applications, cost, and installation techniques. Importance of Understanding Metal Sheet Gauge. Understanding sheet metal gauge, or thickness, is crucial before purchasing. Here’s why: Durability. The gauge of metal .As a DIY enthusiast, I’ve always been fascinated by the versatility of 18 gauge sheet metal. From home renovations to crafting projects, this durable and malleable material has endless possibilities. But what exactly is 18 gauge sheet metal? And how can it .

Learn about 18 gauge sheet metal, its thickness, and applications in automotive, appliances, and HVAC systems. With a balanced thickness of approximately 0.048 inches, 18 gauge metal offers strength and formability, ideal for processes like laser cutting, stamping, and bending.

With its optimal thickness and exceptional strength, 18 gauge sheet metal offers a wide range of applications across various industries. From automotive parts to HVAC systems, this high-quality material provides excellent structural integrity and corrosion resistance. 18 gauge stainless steel is approximately 0.05 inches or 1.27 millimeters thick. This specific thickness balances durability with workability. In the realm of metals and construction, thickness holds significant sway over a material’s application and performance.18 gauge 304 stainless steel offers affordability, durability, and corrosion resistance. It gets favoured for double-bowl kitchen sinks, electrical uses, and craft & model making. How thick is 18 gauge sheet metal? 18 ga thickness corresponds to different measurements for various materials.Superior Strength: Despite its relatively thin profile, 18 gauge cold rolled sheet metal offers excellent strength and durability. It can withstand heavy loads and resist bending or warping, making it suitable for various applications.

18-Gauge: Considered a standard thickness for auto body repair, 18-gauge sheet metal provides a balance of strength, durability, and workability. It is commonly used for patch panels, door skins, and other structural components. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. Learn about the differences between 16 gauge and 18 gauge in carpentry, including strength, durability, applications, cost, and installation techniques.

Importance of Understanding Metal Sheet Gauge. Understanding sheet metal gauge, or thickness, is crucial before purchasing. Here’s why: Durability. The gauge of metal significantly influences the durability of your project or design. Thicker metal can withstand more wear and tear, making it essential for longevity and resilience applications.As a DIY enthusiast, I’ve always been fascinated by the versatility of 18 gauge sheet metal. From home renovations to crafting projects, this durable and malleable material has endless possibilities. But what exactly is 18 gauge sheet metal? And how can it .Learn about 18 gauge sheet metal, its thickness, and applications in automotive, appliances, and HVAC systems. With a balanced thickness of approximately 0.048 inches, 18 gauge metal offers strength and formability, ideal for processes like laser cutting, stamping, and bending.

With its optimal thickness and exceptional strength, 18 gauge sheet metal offers a wide range of applications across various industries. From automotive parts to HVAC systems, this high-quality material provides excellent structural integrity and corrosion resistance.

18 gauge stainless steel is approximately 0.05 inches or 1.27 millimeters thick. This specific thickness balances durability with workability. In the realm of metals and construction, thickness holds significant sway over a material’s application and performance.

18 gauge 304 stainless steel offers affordability, durability, and corrosion resistance. It gets favoured for double-bowl kitchen sinks, electrical uses, and craft & model making. How thick is 18 gauge sheet metal? 18 ga thickness corresponds to different measurements for various materials.Superior Strength: Despite its relatively thin profile, 18 gauge cold rolled sheet metal offers excellent strength and durability. It can withstand heavy loads and resist bending or warping, making it suitable for various applications. 18-Gauge: Considered a standard thickness for auto body repair, 18-gauge sheet metal provides a balance of strength, durability, and workability. It is commonly used for patch panels, door skins, and other structural components.

For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. Learn about the differences between 16 gauge and 18 gauge in carpentry, including strength, durability, applications, cost, and installation techniques.

metal plate gauge thickness chart

sheet metal products for home

18ga sheet metal near me

If your project needs electrical boxes or enclosures, and you don’t know what are the main types of electrical enclosures, you need to read this guide, I will tell you 76 types of electrical boxes for your business based on material, .

18 gauge sheet metal durability|18ga sheet metal near me