electric motor enclosure Prevents the free exchange of air between the inside and outside of the frame, but does not make the frame completely air tight. A fan . See more $5.78

0 · types of electric motor enclosures

1 · totally enclosed motor

2 · totally enclosed fan cooled motor

3 · totally enclosed air over motor

4 · open drip proof motors

5 · odp enclosure vs tefc

6 · motor enclosure opsb meaning

7 · motor enclosure odp vs tefc

Color coded terminals in the ABS box provides a fast, easy way to connect the wires from the trailer connector to the wiring for either a 6-way or 7-way connector. Makes replacing your trailer's connector simple. Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information. Hi everyone.

Allows air to circulate through the windings for cooling, but prevent drops of liquid from falling into motor within a 15 degree angle from vertical. Typically used for indoor applications in relatively clean, dry locations. See morePrevents the free exchange of air between the inside and outside of the frame, but does not make the frame completely air tight. A fan . See more

Similar to a TEFC, but has no cooling fanand relies on convention for cooling. No vent openings, tightly enclosed to prevent the free exchange of air, but not airtight. See moreDesigned to withstand high pressure wash-downsor other high humidity or wet environments. Available on TEAO, TEFC and ENV enclosures totally enclosed, hostile and severe environment motors: See moreDust-tight fan and blower duty motorsdesigned for shaft mounted fans or belt driven fans. The motor must be mounted within the airflow of the fan. See more

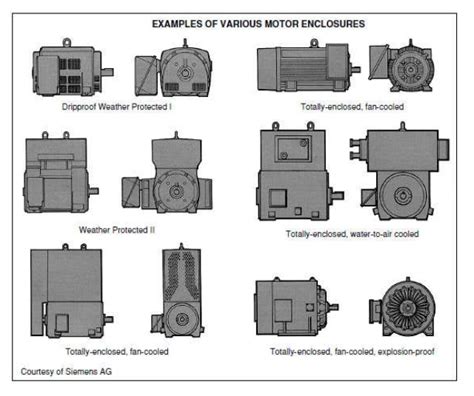

Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 .The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. Nov 4, 2012

The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Drip-Proof Ventilation openings in shield and/or frame prevents .review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor .Selecting the correct electric motor enclosure type is critical for the long-term health of any powertrain. Read on and the find the best enclosure type for your application.

All electric motors (motors) have a housing that contains the working components of the motor. In the U.S., the enclosure describes this housing. The enclosure should meet .

types of electric motor enclosures

The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated . NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of . Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange.

NEMA enclosure classifications versus IEC enclosure classifications. NEMA enclosure classifications are developed by NEMA and used in the U.S./American market. Ingress Protection - IP - ratings are developed by the European Committee for Electro Technical Standardization (CENELEC) (described IEC/EN 60529), and specifies the environmental .There are two types of electric motors that convert electrical energy into mechanical energy by creating a rotational force: alternating (AC) or direct current (DC). Learn about the differences between AC and DC motors. .

The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Drip-Proof Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical.

review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor enclosure types while considering cooling methods, pros/cons, motor size, cost, reliability and .Selecting the correct electric motor enclosure type is critical for the long-term health of any powertrain. Read on and the find the best enclosure type for your application. All electric motors (motors) have a housing that contains the working components of the motor. In the U.S., the enclosure describes this housing. The enclosure should meet specific environmental requirements for restricting foreign objects, such as water, dust, and tools, and safety requirements for personal protection.The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated (TEPV), Air Over (TEAO), Non-Ventilated (TENV), Air to Air (TEAAC), Water to Air (TEWAC), and Explosion-proof (XP); and those with encapsulated or sealed windings.

NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of . Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. NEMA enclosure classifications versus IEC enclosure classifications. NEMA enclosure classifications are developed by NEMA and used in the U.S./American market. Ingress Protection - IP - ratings are developed by the European Committee for Electro Technical Standardization (CENELEC) (described IEC/EN 60529), and specifies the environmental .

There are two types of electric motors that convert electrical energy into mechanical energy by creating a rotational force: alternating (AC) or direct current (DC). Learn about the differences between AC and DC motors. . The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Drip-Proof Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical.

review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor enclosure types while considering cooling methods, pros/cons, motor size, cost, reliability and .Selecting the correct electric motor enclosure type is critical for the long-term health of any powertrain. Read on and the find the best enclosure type for your application. All electric motors (motors) have a housing that contains the working components of the motor. In the U.S., the enclosure describes this housing. The enclosure should meet specific environmental requirements for restricting foreign objects, such as water, dust, and tools, and safety requirements for personal protection.

totally enclosed motor

When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection purposes. In article 300.14, this technique is explained.

electric motor enclosure|totally enclosed air over motor