metallic printing definition in fabric Metallic screen printing creates fabulous fashion items for the right sort of retail market. The impact of your artwork is heightened when rendered in metallic inks and designs achieve a . A junction box is an essential component in electrical wiring that provides a safe and secure enclosure for electrical connections. It is typically made of a metal or plastic material and is designed to protect the wired connections from damage, moisture, and other external elements.

0 · where to buy metallic fabric

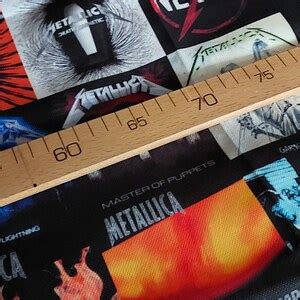

1 · metallica fabric by the yard

2 · metallic quilt fabric collections

3 · metallic fabric for quilting

4 · metallic fabric by the yard

5 · fabric with metallic accents

6 · fabric with gold metallic threads

7 · fabric that looks like metal

$21.23

Considerations for Metallic Ink Screen Printing: Versatility across fabric types. A broad palette of metallic colors for varied design expressions. A smooth finish that complements the fabric's texture. Considerations for Foil Printing: It has a .Metallic screen printing creates fabulous fashion items for the right sort of retail market. The impact of your artwork is heightened when rendered in metallic inks and designs achieve a .

Foil printing involves applying a thin layer of metallic or pigmented foil to fabric using heat and pressure. The foil adheres to the fabric, creating a stunning metallic finish that adds depth and texture to your designs. The benefits of foil .

Metallic fabrics can use the metal to different degrees. Some fabrics have a light embellishment, others a medium level, and others can have the metal densely applied. Golden Galaxy uses a fabric with a complete metallic . Textile printing is the process of applying designs, patterns, or images to fabric. Different types of printing are used in textile industry

Metallic fabric print use shinny or metallic sheer organza with bondaweb. For thin foil transfer use transfoils with bondaweb and for strong metallic use glitter film which no bandaweb is needed to use.Printing techniques are the textile processes by which a thickened dye mixture or print paste is applied to the fabric. These modern processes include flatbed screen, rotary screen, or .

where to buy metallic fabric

Printmaking with metallics can add a real pop to your designs. There are a few different options to choose from when screen printing with metallics: pre-mixed metallic ink, metallic powder and textile foils. We’ve made .

Intense in color, metallic inks are more viscous than other inks. Affiliated with 4-5 times high pigment content than the standard ink, metallic printing imparts concrete vivacious colors onto any fabric.Metallic ink printing combines small particles of copper, zinc, and aluminum to a clear plastisol ink to print the desired design onto your choice of fabric or solid material. Foil printing uses a two-step process by adding a layer of gold or silver leaf over the top of a layer of clear adhesive.

Considerations for Metallic Ink Screen Printing: Versatility across fabric types. A broad palette of metallic colors for varied design expressions. A smooth finish that complements the fabric's texture. Considerations for Foil Printing: It has a gleaming .

Metallic screen printing creates fabulous fashion items for the right sort of retail market. The impact of your artwork is heightened when rendered in metallic inks and designs achieve a unique ‘pop’. Promotional merchandise is given extra appeal when the print literally shines.

metallica fabric by the yard

Foil printing involves applying a thin layer of metallic or pigmented foil to fabric using heat and pressure. The foil adheres to the fabric, creating a stunning metallic finish that adds depth and texture to your designs. The benefits of foil printing on fabric are numerous.

Metallic fabrics can use the metal to different degrees. Some fabrics have a light embellishment, others a medium level, and others can have the metal densely applied. Golden Galaxy uses a fabric with a complete metallic coverage—gorgeous with that blue! Textile printing is the process of applying designs, patterns, or images to fabric. Different types of printing are used in textile industry

Metallic fabric print use shinny or metallic sheer organza with bondaweb. For thin foil transfer use transfoils with bondaweb and for strong metallic use glitter film which no bandaweb is needed to use.Printing techniques are the textile processes by which a thickened dye mixture or print paste is applied to the fabric. These modern processes include flatbed screen, rotary screen, or engraved copper roller printing. Printing is further classified as either dyestuff printing or pigment printing.

Printmaking with metallics can add a real pop to your designs. There are a few different options to choose from when screen printing with metallics: pre-mixed metallic ink, metallic powder and textile foils. We’ve made this project using all three methods to show you the advantages of each one.Intense in color, metallic inks are more viscous than other inks. Affiliated with 4-5 times high pigment content than the standard ink, metallic printing imparts concrete vivacious colors onto any fabric.

Metallic ink printing combines small particles of copper, zinc, and aluminum to a clear plastisol ink to print the desired design onto your choice of fabric or solid material. Foil printing uses a two-step process by adding a layer of gold or silver leaf over the top of a layer of clear adhesive.Considerations for Metallic Ink Screen Printing: Versatility across fabric types. A broad palette of metallic colors for varied design expressions. A smooth finish that complements the fabric's texture. Considerations for Foil Printing: It has a gleaming .Metallic screen printing creates fabulous fashion items for the right sort of retail market. The impact of your artwork is heightened when rendered in metallic inks and designs achieve a unique ‘pop’. Promotional merchandise is given extra appeal when the print literally shines.Foil printing involves applying a thin layer of metallic or pigmented foil to fabric using heat and pressure. The foil adheres to the fabric, creating a stunning metallic finish that adds depth and texture to your designs. The benefits of foil printing on fabric are numerous.

metallic quilt fabric collections

Metallic fabrics can use the metal to different degrees. Some fabrics have a light embellishment, others a medium level, and others can have the metal densely applied. Golden Galaxy uses a fabric with a complete metallic coverage—gorgeous with that blue! Textile printing is the process of applying designs, patterns, or images to fabric. Different types of printing are used in textile industry

Metallic fabric print use shinny or metallic sheer organza with bondaweb. For thin foil transfer use transfoils with bondaweb and for strong metallic use glitter film which no bandaweb is needed to use.Printing techniques are the textile processes by which a thickened dye mixture or print paste is applied to the fabric. These modern processes include flatbed screen, rotary screen, or engraved copper roller printing. Printing is further classified as either dyestuff printing or pigment printing.

24x48 metal house building

240v junction box

What is the yellow wire doing coming from the firewall connection block to the relay? Looks like a cobbled up mess to me, speaking of that is that heavy wire correct going thru the firewall above the solenoid (I haven't traced it out yet).

metallic printing definition in fabric|where to buy metallic fabric