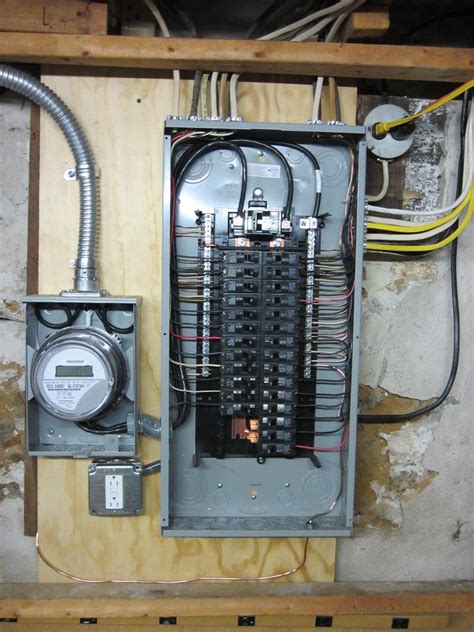

distribution panel box grounding Grounding Bars. The grounding bars are the central safety hub for the panel and the ground wires for circuits connected to the panel. They create a direct path for errant power to be discharged safely to the earth. A septic distribution box, also known as a D-box, is a crucial component of a septic system. Its primary function is to receive the effluent (wastewater) from the septic holding tank and evenly distribute it to the various distribution lines within the drain field or leach field.

0 · main panel grounding diagram

1 · main electrical panelboard grounding

2 · grounding wire electrical panel

3 · grounding tube for main panel

4 · grounding rod for sub panel

5 · grounding in subpanel

6 · grounding for main panel

7 · grounding for electrical installation

I have a few cables that I need to extend as the stud is being moved. I know ideally that tracing them back to the previous socket etc and run new ones would be best, but .

Main Panel has two hot wires and a neutral wire supplied from the meter. Electrician adds a ground wire, which is connected to a grounding source, such as a ground rod. The ground wire is to be connected to the ground bar, .Grounding Bars. The grounding bars are the central safety hub for the panel and the ground wires for circuits connected to the panel. They create a direct path for errant power to be discharged safely to the earth.“Grounding” and “bonding” are important elements of a building’s electrical wiring system. They each have different functions, but they work together to make the building’s electrical wiring safe. This video will show you how to drive grounding rods, run grounding wire to them and into the electrical panel, and how to bond the panel. Driving the grounding rods with a .

You CANNOT use the ground included in say #10/3 wire as your sub panel ground anymore. You are to treat the sub panel just as a service that is coming in from the meter, the only .One final grounding issue: We are often asked if subpanels added at spas and wells can be fed with a three-conductor feeder (two hots and one neutral) and then “grounded” by adding a .

Learn how to ground an electrical panel safely. This guide covers tools, steps, and tips to ensure proper grounding and protection from electrical hazards.The bonding in panels are done two different ways: Main Panel – the neutral wire is bonded (connected) to the ground wire. Sub Panel – the neutral wire is NOT bonded (connected) to the ground wire. What’s the difference between .

If a panel knockout is oversized, concentric, or eccentric - or uses reducing washers - use a bonding jumper, not a standard locknut. The NEC gives you the choice of four methods for ensuring electrical continuity at service . Main Panel has two hot wires and a neutral wire supplied from the meter. Electrician adds a ground wire, which is connected to a grounding source, such as a ground rod. The ground wire is to be connected to the ground bar, .Grounding Bars. The grounding bars are the central safety hub for the panel and the ground wires for circuits connected to the panel. They create a direct path for errant power to be discharged safely to the earth.

First, attach one cable end to the ground rod or neutral bar inside the electrical panel using a size 6 copper grounding wire. To reduce unnecessary bending of the ground path, carefully thread the wire through it.“Grounding” and “bonding” are important elements of a building’s electrical wiring system. They each have different functions, but they work together to make the building’s electrical wiring safe. This video will show you how to drive grounding rods, run grounding wire to them and into the electrical panel, and how to bond the panel. Driving the grounding rods with a demo hammer makes.

You CANNOT use the ground included in say #10/3 wire as your sub panel ground anymore. You are to treat the sub panel just as a service that is coming in from the meter, the only conductors that should be entering your sub panel now are your 2 Hot Feeds, and your Neutral.One final grounding issue: We are often asked if subpanels added at spas and wells can be fed with a three-conductor feeder (two hots and one neutral) and then “grounded” by adding a grounding electrode (grounding rod).

Learn how to ground an electrical panel safely. This guide covers tools, steps, and tips to ensure proper grounding and protection from electrical hazards.

The bonding in panels are done two different ways: Main Panel – the neutral wire is bonded (connected) to the ground wire. Sub Panel – the neutral wire is NOT bonded (connected) to the ground wire. What’s the difference between bonding and grounding? These terms are similar, confusing and often used interchangeably. If a panel knockout is oversized, concentric, or eccentric - or uses reducing washers - use a bonding jumper, not a standard locknut. The NEC gives you the choice of four methods for ensuring electrical continuity at service equipment, service raceways, and service conductor enclosures [250.92(B): Main Panel has two hot wires and a neutral wire supplied from the meter. Electrician adds a ground wire, which is connected to a grounding source, such as a ground rod. The ground wire is to be connected to the ground bar, .

main panel grounding diagram

Grounding Bars. The grounding bars are the central safety hub for the panel and the ground wires for circuits connected to the panel. They create a direct path for errant power to be discharged safely to the earth.

First, attach one cable end to the ground rod or neutral bar inside the electrical panel using a size 6 copper grounding wire. To reduce unnecessary bending of the ground path, carefully thread the wire through it.“Grounding” and “bonding” are important elements of a building’s electrical wiring system. They each have different functions, but they work together to make the building’s electrical wiring safe. This video will show you how to drive grounding rods, run grounding wire to them and into the electrical panel, and how to bond the panel. Driving the grounding rods with a demo hammer makes.

You CANNOT use the ground included in say #10/3 wire as your sub panel ground anymore. You are to treat the sub panel just as a service that is coming in from the meter, the only conductors that should be entering your sub panel now are your 2 Hot Feeds, and your Neutral.

One final grounding issue: We are often asked if subpanels added at spas and wells can be fed with a three-conductor feeder (two hots and one neutral) and then “grounded” by adding a grounding electrode (grounding rod). Learn how to ground an electrical panel safely. This guide covers tools, steps, and tips to ensure proper grounding and protection from electrical hazards.The bonding in panels are done two different ways: Main Panel – the neutral wire is bonded (connected) to the ground wire. Sub Panel – the neutral wire is NOT bonded (connected) to the ground wire. What’s the difference between bonding and grounding? These terms are similar, confusing and often used interchangeably.

main electrical panelboard grounding

The 6-32 screw size is commonly used for outlet screws and cover plates, while 8-32 is often used for light fixture screws and junction boxes that need to support more weight. .

distribution panel box grounding|grounding for electrical installation