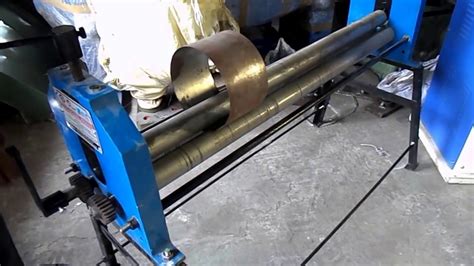

rolling machine for sheet metal Explore Plate Rollers like Sheet Metal Roller with Manual, Motorized and Hydraulic transmission. Find your machine tools and machine services at KNUTH! The breaker box protects your home from electrical hazards and controls the electricity going into your water heater. It's responsible for connecting the electric heater to the plumbing system. Lastly, the hot water heater's first and most important part is the junction box.

0 · types of sheet metal rollers

1 · small sheet metal rolling machine

2 · sheet metal roller bending machine

3 · rolling sheet metal by hand

4 · manual steel plate rolling machine

5 · homemade sheet metal rolling machine

6 · automatic plate rolling machine factories

7 · 3 cylinder sheet metal rollers

$25.95

Choose from our selection of rolling machines, including benchtop rolling mills, sheet metal curvers, and more. In stock and ready to ship.

A plate rolling machine rolls flat sheets into cylinders, with edges that can be welded into pipes. Conical shapes, such as those needed for wind turbine towers, are also possible. Plate rolling machines can bend stainless steel and carbon . A plate rolling machine, also known as a plate roller or sheet metal roller, is a specialized machine tool designed for continuously bending metal sheets into cylindrical, conical, or arc-shaped workpieces. This versatile .Metal rolling machines feed metal sheets, plates, bars, or tubes between rollers or rotating dies to create curves, rolls, beads, or other profile shapes. Slip and plate rolling machines use their .Explore Plate Rollers like Sheet Metal Roller with Manual, Motorized and Hydraulic transmission. Find your machine tools and machine services at KNUTH!

The SR-5016M manual sheet metal rolling machine has a forming width of 50 inches with a capacity of 16 gauge mild steel. Buy a high quality metal roller today.Our plate rolling machines are hydraulic powered up/down & tilting adjustment. All three rollers are driven to reach tight tolerances. This sheet metal roller is the perfect plate bender for all of your fabrication needs.

Sheet metal rolling machines are machines that use rolls, or rotating cylinders, to deform flat sheets of metal into desired shapes and sizes. These rollers, often powered by electric motors, can be adjusted to apply pressure to the metal . The Slip Roll mounts easily to a sturdy bench, providing strength and stability while forming sheet metal. Roller features adjustable knobs that .

This article unveils the fascinating world of metal plate rolling machines, showcasing their types and applications. Learn how these powerful machines bend metal sheets into cylinders, cones, and more, revolutionizing .

On most of our machines, rolling a sheet metal cone shape can be formed by pre-cutting a flat metal blank with the correct inner and outer radius to form the cone (funnel) shape wanted. Normally the blank is fed on one side so that the inner . VEVOR 24 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 16 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers - Amazon.comOur range of rolling machines come in a variety of configurations, from simple round tubing to complex rolled profiles, with a choice of manual or automated operation. Download a Brochure. Request a visit. . You can part exchange your sheet metal and fabrication machinery. You’ll receive a competitive price for your existing machine which .

In the realm of metalworking, metal plate rolling machines stand as crucial equipment for shaping and forming sheet metal into cylindrical or conical forms. With varying types available, choosing the most suitable machine depends on the specific application and material properties. . Top Benefits of Using a Swaging Machine in Sheet Metal . Metal plate rolling machine is a type of equipment that uses work rolls to bend sheet metal, allowing it to form cylindrical, conical, . Four roll plate bending machines are capable of satisfying the entire range of sheet metal rolling requirements and can be equipped with high levels of automation, including automatic up and down feeding .Applications of Sheet Metal Rolling Machines. Sheet metal rolling machines have a wide range of applications in various industries. Some of the common applications include: Automotive industry: Sheet metal rolling machines are used to produce auto body parts, such as doors, hoods, and trunk lids. They can also be used to produce structural .We strive to build a brand reputation of a hundred-year foundation that will last forever and provide the most valuable China 3 Roll Plate Roll, Pipe Bender Rollers, China Four Roll Plate Bending Machine, Sheet Bender and services for the society and the public. As one of the most professional Sheet Metal Rolling Machine manufacturers and suppliers in China, we're .

Baileigh Industrial is an international provider of quality metal machinery. Our proven industry leadership results in profitable solutions for your fabricating needs. Slip & Plate Rolls - Sheet Metal Brakes, Rolls & Shears - Metalworking - Baileigh Industrial VEVOR Mophorn 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers dummy Grizzly Industrial T10727-12" Slip RollMetal sheet rolling machine 12,feet, round; Rolling machines; Aluminium Sheet Rolling Process; Have a Question? Ask our expert. Speak your question. Please enter your question. Manual Wire And Sheet Rolling Machine, 220-240 V ₹ 1,20,000 Get Latest Price. Voltage. 220-240 V. Automatic Grade. Manual. Machine Type. Uses of Sheet Metal Rolling Machines. Sheet metal rolling machines cater to a wide range of applications across various industries. Automotive Industry: Used to shape sheet metal parts for car bodies, frames, and exhaust systems. The precision and consistency of these machines ensure high-quality components. Aerospace Industry:

cone rolling machine rolling a cone sheet metal【sheet metal cone roller】sheet metal cone rolling. One of the main disadvantages is that it can be difficult to achieve precise control over the curvature of the plate, particularly with thicker plates. This can result in the formation of flat spots or other deformities, which can compromise . Sheet metal rolling machines, the unsung heroes of the industry, empower manufacturers to achieve exceptional accuracy and consistency in their designs. Their ability to manipulate metal sheets with unparalleled precision unlocks a world of possibilities, shaping the future of industries from automotive to aerospace. .

Our hydraulic plate rolling machines, aka pinch roller machines are made for rolling sheet metal plates in a simple operation. Equipped with a robust and quiet German Rexroth hydraulic logic system to clamp your workpiece with ease. Our heavy duty plate bending machine is made of high grade alloy steel and hardened 50-52 HRC. The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Operating sheet metal rolling machines requires a keen awareness of potential hazards and a commitment to safety practices. By adhering to the principles outlined above, operators can mitigate risks, prevent injuries, and ensure a safe working environment. Remember, safety is not merely a slogan; it is an indispensable cornerstone in the realm .2024 best sheet metal rolling machine, affordable sheet metal plate rolling machine for sale, Buy cheap metal rolling machine at cost price from 2024 top-rated sheet rolling machine manufacturer. +86-18052080815 | [email protected]

VEVOR Slip Roll Machine, 24 inches Forming Width in 16 Gauge Capacity, Sheet Metal Slip Roller Rolling Bending Machine, with 2 Detachable Rollers for Low Carbon Steel Copper Sheet Aluminum Alloy Sheet - Amazon.com

types of sheet metal rollers

This device is designed to be a rolling machine for sheet metal. Please understand that the design is not perfect. Parts that you need to buy: Six 608ZZ bearings ; Two 697ZZ bearings for the handle ; Two M6X1 Bolts, I used 96mm long bolts; Two M6X1 Nuts; Twelve drywall screws different lengths, better have an assortment on handShop VEVOR 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers at lowest price, 2-day delivery, 30-day returns. Shop now at VEVOR.

Sheet metal rolling machines offer a vast repertoire of techniques designed to cater to diverse applications. Whether it’s the classic 3-roll bending, where the sheet metal is shaped between three rolls, or the intricate cone rolling, where a conical shape is imparted, the versatility of these machines knows no bounds. .3 roller metal sheet rolling machine. Besides the fact that all machines in this category come with three rollers, the other difference between the three plate rollers . And the two roll bending machines is the fact that they give you more control over the intended output shape. There are many types of three roller machines in this category .Metal sheet rolling machine is economical plate bending machine, it is an economical plate bending machine it has a pre-bending function for a maximum of 6mm and a minimum of 2mm; the length is between 1000-2000 mm , and it is one of the best choices for thin plates.

DIY Manual Plate Rolling Machine Soft Metal Sheet Mini Bending Machine S/N:20013. Opens in a new window or tab. Brand New. .80. or Best Offer +.99 shipping. from China. 3 watchers. Sponsored. eximiousmall (78) 100%. GREAT PRICE Great price compared to .

Various Sheet Metal Rolling Machine. RBE-LSAW Pipe Mill Production Line. Dish End Drum Presser. Dish End Flanging Spinning Machine. Profile Bending Machine. 12m Long Oil Gas Pipe Making Machine. Our Partner. Ryosho,Japan. HDLW12-160*3500 4-Roller Plate Rolling Machine. Max thickness: 160mm, Max width: 3500mm. Rolling Machines: Beyond Sheet Metal Production. While rolling machines are most commonly associated with sheet metal production, they are used in other metalworking applications. For example, a rolling machine can bend raw metal to achieve unique shapes. By definition, however, rolling machines — when used in the context of metalworking .This 3-roller bending/rolling machine is designed for rolling thin metal sheet with max. thickness of 2mm.This is powered by 1.5Kw motor and can roll forward and backward with a switch installed. Fast Shipping on JHT Machine Tools, Call Us: +86-0555-6719123 or +86-18255518925

distribution processing center po box 1748 kennesaw georgia

The National Electrical Code (NEC) requires that an outlet box for a washing machine be at least 18 inches off of the ground. There are some special circumstances in which an outlet box can be as low as 12 inches off of the ground, but these are rare cases.

rolling machine for sheet metal|rolling sheet metal by hand