g code cnc machine Transfer to CNC Machine: After post-processing, the finalized G-code is transferred to the CNC machine, where it is executed to control the machine’s movements and operations. By automating the conversion of CAD designs into G-code, CNC machines allow for precise and repeatable manufacturing processes, drastically reducing the time and effort . Weldon’s fabrication capabilities are unlimited. Oval duct, 100″ round, or insulated double-walled duct is nothing out of the ordinary for Weldon Fabrication. Whether it is in house or out-of-house, Weldon can fabricate it for you.

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

Get everything fitted well, using self-tapping sheet metal screws to hold the new panel in place while you trim and fit. The self-tappers are great because you can remove the pan to trim it multiple times, and put it back in the same place during fitting.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. CNC Machine G-Code Tutorial – List Of G-Codes For CNC Programming | CNCLATHING . 2021.2.26 . For a CNC machine tool, to make it move and complete the processing of a part, programming is an essential step. For a part of the processing quality, depends on the quality of its program. Therefore, a good program is also very important!

Transfer to CNC Machine: After post-processing, the finalized G-code is transferred to the CNC machine, where it is executed to control the machine’s movements and operations. By automating the conversion of CAD designs into G-code, CNC machines allow for precise and repeatable manufacturing processes, drastically reducing the time and effort . For example, there’s StickFont V3 that converts text into g code for machining, as well as SketchNC which allows you to convert drawings into g code. Feature NCPlot; Price: 9: User Interface . There are a variety of .G-Code Programming . Foundation GCode Course; CNC Lathe Programming; CNC Mill Programming; CNC Macro Programming; 4-Course GCode Bundle; CAD/CAM . Fusion 360 for CNC Mills; Fusion 360 for CNC Lathes; Machine Shop Maths . Machine Shop Maths Course; Speeds and Feeds - mini-course; Metrology - GD&T . measuring equipment; Machine Shop .

CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions. Understanding these languages is vital for effective communication with your machine, enabling you to translate digital designs into physical parts with accuracy.List of G-codes commonly found on Fanuc and similarly designed cnc controls.G code are also called preparatory codes (preparatory functions). ≡ MENU. Home Fanuc Learn Examples Sinumerik . Mazak G code list for cnc machinists who work on MAZAK machining centers. Mazak G Code List G Code Function G00 Positioning G01 Linear interpolation G01.1 . Format for using an N code. The N-code should be the first thing on every block (line) of the program. This is how it looks in practice: N10 G90 F100 S1200 T01.01 N20 G00 X36 Z10 N30 X26 Z2 N40 G01 Z-12 M03 N50 X36 M05 N60 G00 Z10 N70 M30. Notice how the N numbers jump up by 10 on each line.codes / G codes G stands for ‘Geometric code’. This code is used to instruct the machine where to move, how fast to move and which path to follow. G-code is also known as the ‘Preparatory code’, “G” is followed by number which is a command to change the geometry. List of Preparatory functions (G codes) Sl no Functions Syntax

Explanation of G-Code and M-Code in CNC Machines. G and M codes are two common programming languages in CNC programming with specific distinctions. While G code, or geometrical code, deals with the machine’s movement and the cutter’s transverse direction, it is a relatively more comprehensive code. In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications. This article will teach beginners as well as seasoned professionals how to program .

In CNC machining, G-code is the most important language of all languages used to program computer numerical control (CNC) tools. It is necessary for effective operation and programming alike. Among many commands needed for accurate machine control, one that deserves special attention is the G09 code. This article explains what G09 does as a CNC . Before delving into where you can source free G-Code files, let’s first discuss the different G-Code file types that exist. Here is the list of G-Code file types: 1 .cnc files. These are g-code files created by CAD/CAM programs such as QuickCam and PartMaster CAM among others to generate paths for CNC milling machine tools. The machine tool monitoring that many CNC machining facilities are doing today could be a first step toward their use of machine learning. In this conversation, MMS’s “Data Matters” columnist Matt Danford speculates on the coming role of .

Universal G code sender is a very popular free CNC software. It is not universally compatible with all controllers, but it works with GRBL, TinyG, and Smoothieware. . I built my own DIY CNC machine from scratch, welding metals to make a rigid CNC body, and making CNC control systems for powerful motors. . G-code is a type of CNC programming language used for controlling the functions of a CNC machine that relate to the movement of the cutting tool.. It stands for ‘Geometric code’. G-code consists of instructions that .

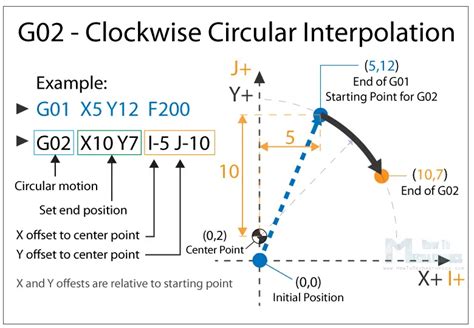

Making a (G code) programs for a lot of mechanical products and manufacturing it in CNC machines (Milling 3 Axis, Multi Axis). Have strong knowledge of mold wizard of NX (Injection Mold Plastic ) Making a complete mold base for plastic parts and get . This means the software will convert the vector graphics in the SVG file to G-code instructions for your CNC machine. A common challenge when converting an image to g-code is the original image’s quality. If the image .What is G02 g-code? G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the effective mode . This type of movement is called Circular interpolation.

how to understand g code

Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series This lesson is part of a online course for CNC router owners available here:https://gcodetutor.com/cnc-router-programming.htmlThe best way to learn G-Code is.

sheboyban custom metal fabrication

In Computer Numerical Control (CNC) machining, the finished product and the performance requirements depend on precision and accuracy. G28 G-Code is essential, as it is utilized to move the machine to the previously established reference point, referred to as the home or zero position. This article is concerned with G28 command usage and the G-code . Throughout the exploration of CNC machine codes, we’ve delved into the intricacies of G-code and M-code, highlighting their indispensable role in modern machining processes. By dissecting codes from G00 for Rapid Positioning to G21 for Millimeter System Selection, we’ve seen how each code serves a specific function, contributing to the .

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool. These codes instruct the machine on how to move, such as .Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill SeriesUnderstanding G and M codes is crucial for CNC programmers, operators, and manufacturing professionals. It allows them to create efficient programs, optimize machining processes, and troubleshoot issues effectively. FAQs about G and M Codes in CNC Machining. Q: What is the best way to learn G and M code programming? A: Practice with hands-on . This type of G code is called a modal command. Modal commands remain in effect until they are canceled or changed to another code in the same group. . All of the codes listed in the table below are modal commands that affect the way the CNC machine interprets size and location values that are entered.

G00 is used to move the machine axes at the maximum speed. It is primarily used to quickly position the machine to a given point before each feed (cutting) command. This G code is modal, so a block with G00 causes all following blocks to be .

g code explained with examples

g code commands cheat sheet

Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks! .023 sounds right for sheet metal. They recommend s6. The difference between 2,3, and 6 is the percentage of silicone. The higher the percent, the more fluid the puddle is.

g code cnc machine|cnc mill g code list