application of cnc machine wikipedia Motion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more JUNCTION: BOX MODEL XP-JB • Many types available • Any circuit configuration available. SINGLE CIRCUIT CONTROL BOXES MODEL CB • .01 shunt standard • 25 watt 1 ohm .

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines Wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

$8.17

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into . See moreMotion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more

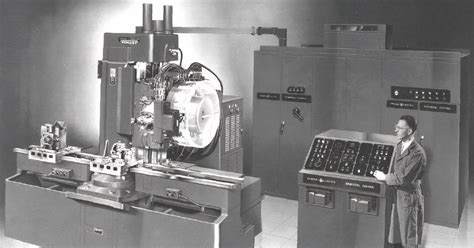

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See moreMany other tools have CNC variants, including:• 3D printing• See more

Within the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See moreNow the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See moreIn CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See moreIn numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See more

Early commercial applications of CAM were in large companies in the automotive and aerospace industries; for example, Pierre Béziers work developing the CAD/CAM application UNISURF in the 1960s for car body design and tooling at Renault. Alexander Hammer at DeLaval Steam Turbine Company invented a technique to progressively drill turbine blades out of a solid metal block of metal with the drill controlled by a punch card reader in 1950. Boeing first obtained NC machine.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots . CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, . CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any .

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and . What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non .CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a .In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.

CAD model and CNC machined part. Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining [1] [2] [3] is the use of software to control machine tools in the manufacturing of work pieces. [4] [5] [6] [7] [8] This is not the only definition for CAM, but it is the most common. [4]A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation. What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non-negotiable.

who invented the cnc machine

when were cnc machines invented

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.CAD model and CNC machined part. Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining [1] [2] [3] is the use of software to control machine tools in the manufacturing of work pieces. [4] [5] [6] [7] [8] This is not the only definition for CAM, but it is the most common. [4]

computer numerically controlled machines

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.

cnc machines Wikipedia

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation.

cnc machine meaning in english

What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non-negotiable.

$25.00

application of cnc machine wikipedia|who invented the cnc machine