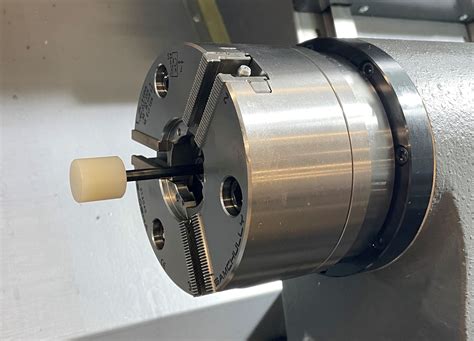

cnc lathe parts ejector quotes Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible. TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise heat input and weld placement.

0 · lathe sub spindle ejector

1 · lathe ejector parts diagram

Get the best deals for Western Electric Wood Wall Telephone at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

Line the part ejector [1] up with the hole in the sub spindle, and press it in. The part ejector [1] will stop against an internal lip in the draw bar [2], press it in until movement stops. Note: The sub spindle jaws may need to be . When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big .Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible.Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches.

Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, with one tip, approximately 0.750 in diameter. This .SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter .

Line the part ejector [1] up with the hole in the sub spindle, and press it in. The part ejector [1] will stop against an internal lip in the draw bar [2], press it in until movement stops. Note: The sub spindle jaws may need to be unclamped or removed for . When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big bill to repair the damage. If you are plagued by this problem, you will be interested in the Subspindle Part Ejection Device (SPED) made by Zenna Industries.Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible.Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches.

Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, with one tip, approximately 0.750 in diameter. This tip will not eject a part smaller than the diameter, and in fact, may hit the back of the collet before reaching full extension, causing an alarm (2053 – Work ejector time over).SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter 20mm; Flexible tooling layouts allow for endless variations of complex machiningEnter your dimensions, material, finish, and features your part needs and let our Instant Quote algorithm give you immediate pricing. Want to speak to speak with a design engineer regarding your project? Fixed prices are available right online! Upload your design, see your price, and get your parts in as little as 5 days.Manufacturer of CNC lathe accessories including part ejectors with adjustable spring ejection force feature. Made in USA.

I just looked at my ID collets (Small to medium 5C) and there is not a lot of room to install an effective ejector. Also not sure how long the pins will need to eject to clear the part off the collet. A failure to eject may get expensive.

lathe sub spindle ejector

lathe ejector parts diagram

JUSTWAY:From prototypes to end parts, it faster & easier to order custom prototype parts for CNC machining, 3D printing, injection molding, and urethane casting. Get an instant quote. . 5-Axis Milling, Lathe, Deep Hole Drilling, EDM, etc Machines 100+ . Line the part ejector [1] up with the hole in the sub spindle, and press it in. The part ejector [1] will stop against an internal lip in the draw bar [2], press it in until movement stops. Note: The sub spindle jaws may need to be unclamped or removed for .

When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big bill to repair the damage. If you are plagued by this problem, you will be interested in the Subspindle Part Ejection Device (SPED) made by Zenna Industries.

Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible.Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches. Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, with one tip, approximately 0.750 in diameter. This tip will not eject a part smaller than the diameter, and in fact, may hit the back of the collet before reaching full extension, causing an alarm (2053 – Work ejector time over).

SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter 20mm; Flexible tooling layouts allow for endless variations of complex machiningEnter your dimensions, material, finish, and features your part needs and let our Instant Quote algorithm give you immediate pricing. Want to speak to speak with a design engineer regarding your project? Fixed prices are available right online! Upload your design, see your price, and get your parts in as little as 5 days.Manufacturer of CNC lathe accessories including part ejectors with adjustable spring ejection force feature. Made in USA.

I just looked at my ID collets (Small to medium 5C) and there is not a lot of room to install an effective ejector. Also not sure how long the pins will need to eject to clear the part off the collet. A failure to eject may get expensive.

wholesale dfm metal precision injection mould design customized manufacturer

What is a Wells Cargo Junction Box Wiring Diagram? A Wells Cargo junction box wiring diagram is a detailed drawing used to troubleshoot and diagnose electrical system issues. It is also referred to as a schematic.

cnc lathe parts ejector quotes|lathe ejector parts diagram