solidworks flatten non sheet metal part In this tech tip learn how to flatten a dumb solid in SOLIDWORKS to obtain a flat pattern from an imported .STEP or .IGES sheet metal part file. Electrical boxes are an essential part of any home electrical system. There are several types of electrical boxes, and they all house wiring connections, the parts of your electrical system where wires join an outlet, switch, or even other wires.

0 · solidworks flattened surface

1 · solidworks flatten surface template

2 · solidworks flatten sketches

3 · solidworks flatten sheets

4 · solidworks flatten sheet metal

5 · solidworks flatten chart

6 · solidworks flatten

7 · how to flatten solidworks

Ceiling fan junction boxes are an important component of any home. They provide a secure connection for the wiring of the fan, and they come in two main varieties: plastic and metal. Installing a junction box is not a difficult task, and it can usually be done in a few simple steps.

This is useful when working with developable surfaces such as sheet metal parts with non-standard bends. The SOLIDWORKS software can flatten developable and non-developable .SOLIDWORKS can any face, surface, or set of faces to create templates for .You can individually flatten any body in a multibody sheet metal part. To increase . In this tech tip learn how to flatten a dumb solid in SOLIDWORKS to obtain a flat pattern from an imported .STEP or .IGES sheet metal part file.

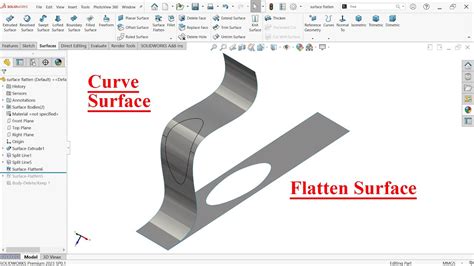

Starting in 2015, SOLIDWORKS has included a new surface feature called “Flatten Surface” for SOLIDWORKS Premium users. This functionality is useful for creating templates .

SOLIDWORKS can any face, surface, or set of faces to create templates for manufacturing. This is useful when working with developable surfaces such as sheet metal parts with non-standard .The reason I'd like a flat part to have a flat pattern is that I want to use a macro to make a DXF of all of the parts we are going to cut. In inventor a great way to .

Does anyone know of a way to take a non-sheet metal part, for example a flat ring that has flat teeth on the inner surface, and fold it out into a flat pattern. I tried using the flex tool, but it . First, it won't flatten because it's not a sheet metal part. I would suggest creating it as a lofted sheet metal part. Actually, the first thing you might want to do is check out the help .

solidworks flattened surface

You can do this by adding a sheet metal feature to your existing part. Have a look at the help files for sheet metal, there is an example of flattening a cone or cylinder that should .At times when creating drawings of sheet metal parts you may find that the flat-pattern view will not appear flat, but instead as another random view: This issue is often caused by the flattened configuration not properly being enabled using .You can individually flatten any body in a multibody sheet metal part. To increase performance when flattening sheet metal bodies with a large number of patterns, click Tools > Options > .

To flatten a body, do one: In the FeatureManager design tree, select the part and click Flatten (Sheet Metal toolbar).; In the cut list, right-click the body and click Flatten.; In either the FeatureManager design tree or the cut list, right-click the Flat-Pattern feature for the part and click Unsuppress.; To return the part to its bent state:

Flatten Sheet Metal Part Example (VBA) This example shows how to flatten a sheet metal part. '----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Open the Immediate window. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .

Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model .The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . flatten a non-planar face. RL By Rob Lenicheck 10/18/15. I am trying to flatten a sheet metal part. Works fine for perpendicular faces but three of the faces I want to flatten are curves and are not accepted because they are "non-planar". Suggestions?You can flatten all the bends of a sheet metal part at once. . 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. To provide feedback on individual help topics .I'm guessing this was converted from a scan or involves a twist of some kind to make it non-analytical. I've been able to flatten round rolled parts before with a small tab cheat, basically extend a tiny face out to a flat edge, use that to insert bends, and then cut the tab off in the flat pattern configuration.

When you create a part initially out of sheet metal you can use the Base Flange tool with an open or closed profile sketch. This eliminates extra steps because you create a part as sheet metal from the initial design stage. Build a part, shell it, and then insert sheet metal bends. If you build a solid using non-sheet metal features, you need .You can add bend lines to a flat face of a sheet metal part with a sketched bend feature. This lets you dimension the bend line to other geometry. . you can normalize all non-normal side walls in sheet metal models. Parent topicSheet Metal. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the .I have a sheet metal part, which I was able to flatten in the past. Now it won’t do it. See: When the feature tree shows the flat pattern as suppressed. The part looks like this: With the flattened pattern enabled. very little happens to the part: If anything, it isn’t flattned. What could be the cause of this? I am doing this in SolidWorks .You can flatten the bends in a sheet metal part in the following ways: To flatten the entire part, if the Flat-Pattern1 feature is present, unsuppress Flat-Pattern1, . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about .

You can flatten all the bends of a sheet metal part at once. . 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. To provide feedback on individual help topics .macro will not proceed unless only 1 Solidworks file is open. - Export file(s) must contain a Sheet-Metal body, or the export tool will skip over that file. This is particularly useful for large assemblies that contain lots of non-sheet metal bodies, such as hardware, weldments, surfaces.10) Designing Sheet Metal From the Flat When designing sheet metal parts from the flat, it is important that every feature you create have the proper reliefs, and that these reliefs belong to the feature you create. You must either create the bend reliefs before the bend operation (that is, create the feature), or create the I have created a fairly simple sheet metal part, long rectangle shaped base-flange with 2 short sketched bends, and then I add a miter flange to one side. The flange is added with no problem, except the "Miterbends" are not placed in the feature, if .

This is useful when working with developable surfaces such as sheet metal parts with non-standard bends. The SOLIDWORKS software can flatten developable and non-developable surfaces and faces. A developable surface is a surface that can be flattened onto a plane without distortion. Non-developable surfaces and faces deform when flattened.

Flatten a non-sheet metal part. Thread starter ady_mech; Start date Jun 7, 2007; Jun 7, 2007 #1 A. . this so that I can make a 2D drawinng that can be given to a fabricator so that he can make that out of a flat sheet of metal. I can't seem to do this in Solidworks 2006. There is a feature to flatten parts but inly if they are made using .

The "convert to sheet metal" command isn't getting me what I want and the "insert bends" command ends up making the edges of the channel turn in to sheet metal bends. I have a decent work around where I start by modeling the sheet metal features I want and then extrude the channel in chunks, merging all of the bodies together. Ever wonder why your sheet metal drawing view doesn't flatten after you've made a change? We'll be going over 2 ways to make sure your change sticks while pr.You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).

SolidWorks will then ask you what you want to include in the new mirrored part. The item you must check is “Break link to part”. That is the only way you will get the full functionality of the sheet metal features in your new part. If you do not check it then all you will get is the solid body in the new part. Ketul Computer Aided .In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress.; Select Process-Bends and all of the features after it. Click Edit > Suppress > This Configuration to .

Flatten Sheet Metal Part Example (VBA) This example shows how to flatten a sheet metal part. '----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Open the Immediate window. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .By selecting an edge on a cylindrical or conical face, you can flatten the part as sheet metal. Slot Propagation. When creating a tab and slot feature in an assembly component, you can propagate the slots to other instances of the same component in the assembly. Stamp ToolFor Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Any idea why this part won't let me flatten? . Sheet metal won't flatten - simple part. VV By Valery Volkov 07/17/20. Any idea why this part won't let me flatten? Uploaded part (SW 2019 + STEP) -Val. answers: 14. View or Reply .

This is useful when working with developable surfaces such as sheet metal parts with non-standard bends. The SOLIDWORKS software can flatten developable and non-developable surfaces and faces. A developable surface is a surface that can be flattened onto a plane without distortion. Non-developable surfaces and faces deform when flattened.

22 gun steel security cabinet

20mm steel conduit box

$3,330.31

solidworks flatten non sheet metal part|solidworks flattened surface