anodized aluminum machining spare parts with cnc Anodized aluminum parts are one of the toughest and most versatile metal products on the market. Low cost, High Value. Because anodized aluminum is much lighter than other metal products, the cost of transportation to the job site or . Our production range includes CNC processing center, automatic lathing, automatic milling, wire cutting, powder metallurgy processing and assembly of metal parts with plastic parts.

0 · does anodizing aluminum work

1 · anodizing aluminum parts natural

2 · anodized aluminum parts cleaning

3 · anodized aluminum parts

4 · anodized aluminum industrial applications

5 · anodized aluminum for marine

6 · anodized aluminum

7 · aluminum anodizing process

Machining CNC Auto Parts - Manufacturers, Factory, Suppliers from China Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality .

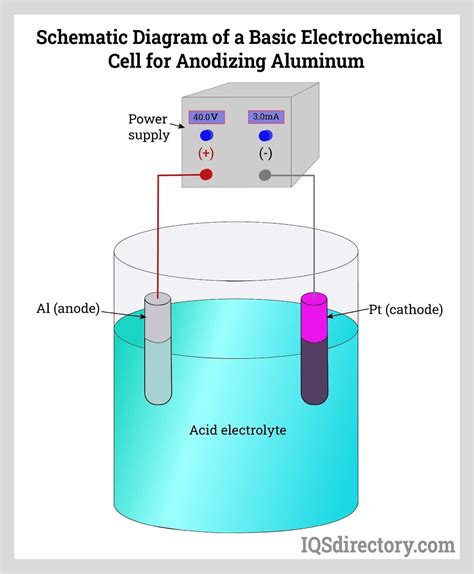

Anodized aluminum is treated aluminum with excellent durability. To produce anodic aluminum oxide, use an electrochemical process in which the metal is immersed in a series of tanks, and the anode layer in one of the tanks is grown from the metal itself. Anodizing is an electrochemical process that . See moreIn order to anodic aluminum parts correctly, must clean and rinse the surface, and then place aluminum parts in an electrolyte . See moreThere are several types of aluminum anodizing, each of which results in a unique anodic coating. Most commonly referred to as Type I-Chromic Acid Anodize, Type II . See moreOur aluminum CNC machining services include an anodizing treatment surface that enhances both the appearance and durability of our products. This process not only provides a sleek, .

does anodizing aluminum work

anodizing aluminum parts natural

Anodized aluminum parts are one of the toughest and most versatile metal products on the market. Low cost, High Value. Because anodized aluminum is much lighter than other metal products, the cost of transportation to the job site or .Our aluminum CNC machining services include an anodizing treatment surface that enhances both the appearance and durability of our products. This process not only provides a sleek, modern finish but also improves resistance to corrosion and wear. We offer custom OEM services to cater to your specific needs in aluminum CNC machining. Whether you .

Discover the benefits and process of anodizing aluminum for CNC machining, enhancing durability and corrosion resistance in precision parts.

Anodizing improves the strength-to-weight ratio of aluminum, making it more corrosion resistant, and helps to create a hard, protective covering to the part's surface. This method also allows for a wide range of color possibilities for anodized Aluminum Turning Parts .

We have advanced anodized equipment, which can provide anodizing services for a variety of metals and provide low-cost and high-quality anodized finishing solutions. Now start your anodized aluminum project, manufacture on demand and deliver on time.Jiesheng Hardware is a manufacturer precision hardware spare parts, CNC parts suppliers, CNC machining service, Milling parts, Turning parts, Machining parts, Machined parts screws, Nuts, Sshafts, StandoffsIn the manufacturing industry, CNC machining with anodization has transformed the production of spare parts, providing superior precision, durability, and customization.

At its core, anodizing is an electrochemical process that transforms the aluminum surface into a corrosion-resistant, anodic oxide finish. This finish is integrated with the underlying aluminum substrate, unlike surface-level treatments such as paint or plating.

Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum anodizing are available from Protolabs: Type I-Chromic Acid: Provides a whisper-thin but still durable coating.Follow our steps and you will know how to anodized aluminum. Step 1: Clean Aluminum Parts to Remove Impurities. The aluminum part undergoes a cleaning process to remove impurities that may interfere with the anodizing process. Step 2: Constructing the Film Layer. Once the cleaning process is complete, the next step involves the anodizing process. Anodized aluminum parts are one of the toughest and most versatile metal products on the market. Low cost, High Value. Because anodized aluminum is much lighter than other metal products, the cost of transportation to the job site or .Our aluminum CNC machining services include an anodizing treatment surface that enhances both the appearance and durability of our products. This process not only provides a sleek, modern finish but also improves resistance to corrosion and wear. We offer custom OEM services to cater to your specific needs in aluminum CNC machining. Whether you .

Discover the benefits and process of anodizing aluminum for CNC machining, enhancing durability and corrosion resistance in precision parts. Anodizing improves the strength-to-weight ratio of aluminum, making it more corrosion resistant, and helps to create a hard, protective covering to the part's surface. This method also allows for a wide range of color possibilities for anodized Aluminum Turning Parts .We have advanced anodized equipment, which can provide anodizing services for a variety of metals and provide low-cost and high-quality anodized finishing solutions. Now start your anodized aluminum project, manufacture on demand and deliver on time.

anodized aluminum parts cleaning

Jiesheng Hardware is a manufacturer precision hardware spare parts, CNC parts suppliers, CNC machining service, Milling parts, Turning parts, Machining parts, Machined parts screws, Nuts, Sshafts, Standoffs

In the manufacturing industry, CNC machining with anodization has transformed the production of spare parts, providing superior precision, durability, and customization.At its core, anodizing is an electrochemical process that transforms the aluminum surface into a corrosion-resistant, anodic oxide finish. This finish is integrated with the underlying aluminum substrate, unlike surface-level treatments such as paint or plating.

Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum anodizing are available from Protolabs: Type I-Chromic Acid: Provides a whisper-thin but still durable coating.

You can buy high-caliber brass parts from us. With high precision and sharp finishing, we provide brass parts with everlasting quality. We utilize CNC lathe turning machines. We also employ CNC milling machines. These machines optimize the features of metallic parts. You have a wide range of options. Whether you need plastic CNC parts or .

anodized aluminum machining spare parts with cnc|anodized aluminum