adative manufacturing cnc Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is . As a leading stamping part factory, Atlas metal transform sheet metal into complex small metal stamping parts using highly specialized computer-aided drafting and manufacturing programs during the stamping process.

0 · cnc vs additive manufacturing

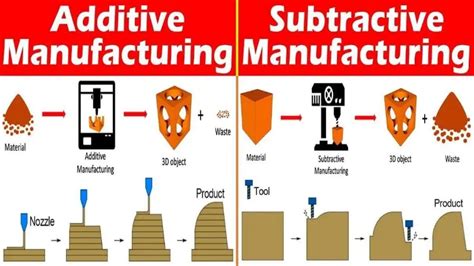

1 · cnc machining additive powder

2 · additive manufacturing subtractive

3 · additive manufacturing services

From attractive, extremely durable garage cabinets to slatwall to overhead racks, GarageCabinets.com has everything you need to get your garage organized for good. You'll deal directly with the manufacturer, so we can pass the savings on to you.

Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) .

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for . Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive .

Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long. For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material . Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.

Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has been most commonly used to create tooling, fixtures and prototypes with polymer materials.

cnc vs additive manufacturing

Machine shops continue to evolve in how they use 3D printing technology in additive manufacturing, though traditional CNC machining – think of it as subtractive manufacturing – still has a solid footing. Electing one or the other depends on a number of different factors.Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long. For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.

robinson metal packer house

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material .

rj metal fabrication

cnc machining additive powder

Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop. When additive manufacturing (AM) is applied in a precision turned parts machine shop it has been most commonly used to create tooling, fixtures and prototypes with polymer materials.

additive manufacturing subtractive

CNCPros.com offers a wide variety of parts designed to fit your Fadal like Ballscrews, ATC clips, spindles, resolvers, amplifiers, inverters and more – all on-the-shelf, ready-to-ship today! Lowest prices on the things you really need. Over $2,000,000 in rolling stock so you know if you need it, we have it. Free technical support by phone, fax or email.

adative manufacturing cnc|additive manufacturing subtractive