average time savings cnc versus manual machining Some primary industries that use CNC machining are: 1. Consumer Electronics Electronics manufacturers often use CNC machining to manufacture housings, fixtures, PCBs, and jigs for the electronics industries. The most famous market is mobile phones and . See more Flat-ended studs, whether uncoated or galvanized, cannot be welded to galvanized plate because the alloy layers in the zinc coating appear to act as a low friction-bearing . See more

0 · manual machining vs manual lathe

1 · manual machining vs cnc

2 · manual machining definition

3 · manual lathe vs cnc machining

4 · manual cnc machining

5 · difference between cnc and manual

6 · cnc vs manual machining cost

We make these all-welded storage cabinets using 14-gauge steel. Lyon all-welded steel storage cabinets include heavy-duty steel doors. Doors are hung on heavy-duty 5/16″ brass pin hinges. Hinges are securely welded to each door. The heavy-duty hinges will help keep the doors align and close flush.

You can also compare and contrast manual machining and CNC machining by understanding the advantages of each. See more

This part will show you the cost difference between CNC machining vs manual machining, Major cost differences are as follows: See moreSome primary industries that use CNC machining are: 1. Consumer Electronics Electronics manufacturers often use CNC machining to manufacture housings, fixtures, PCBs, and jigs for the electronics industries. The most famous market is mobile phones and . See moreThere is simply a comparison between CNC machining vs manual machining. It is unreasonable to expect that manual machining will offer you the result that CNC machining . See moreExplore the essential differences between CNC machining vs manual machining, including precision, speed, and skill requirements for optimal use

Using CNC machines offers numerous advantages over manual machines, including higher precision, consistent quality across large production runs and the ability to perform complex cuts and shapes that would be difficult . CNC machining offers several advantages over manual machining: • Precision and Accuracy: CNC machines operate with high precision and accuracy, consistently producing .

While CNC Machining leverages automation and precision, manual machining offers traditional craftsmanship. Learn more about CNC Machining in our comprehensive .One of the main advantages - between CNC vs manual machining - is the reduced labour costs associated with CNC methods. With manual techniques, skilled operators are required to manually operate the machines, which can be .

CNC machining is highly efficient and significantly faster compared to manual machining. Once the program is set, CNC machines can work continuously with minimal human intervention, .

CNC machining processes are much more precise than their manual counterparts and can reproduce identical components based on tolerance requirements with ease. The . When it comes to manufacturing, there are two main methods of machining: CNC machining and manual machining. While both approaches can produce high-quality parts, they differ in terms of efficiency, accuracy, and . To name a couple, CNC machining minimizes the amount of interaction between the operator and the machine tool, and significantly reduces the active machining time. But is this always the more efficient or fastest way .

If you’re choosing which method to use for your business, here’s a detailed comparison between CNC machining vs Manual machining to help you make the best choice for your custom prototypes and end-use production parts.Explore the essential differences between CNC machining vs manual machining, including precision, speed, and skill requirements for optimal use Using CNC machines offers numerous advantages over manual machines, including higher precision, consistent quality across large production runs and the ability to perform complex cuts and shapes that would be difficult or impossible with manual machining. CNC machining offers several advantages over manual machining: • Precision and Accuracy: CNC machines operate with high precision and accuracy, consistently producing parts with tight tolerances. The computerized controls eliminate human errors and variations, ensuring precise and repeatable results.

While CNC Machining leverages automation and precision, manual machining offers traditional craftsmanship. Learn more about CNC Machining in our comprehensive guide. The decision between CNC vs manual machining affects more than production; it impacts efficiency, cost, and quality.One of the main advantages - between CNC vs manual machining - is the reduced labour costs associated with CNC methods. With manual techniques, skilled operators are required to manually operate the machines, which can be time-consuming and costly.CNC machining is highly efficient and significantly faster compared to manual machining. Once the program is set, CNC machines can work continuously with minimal human intervention, enabling faster production rates. Conversely, manual machining can be time-consuming, especially for intricate designs or complex operations that require multiple . CNC machining processes are much more precise than their manual counterparts and can reproduce identical components based on tolerance requirements with ease. The secondary advantage CNC machining provides over manual machining is .

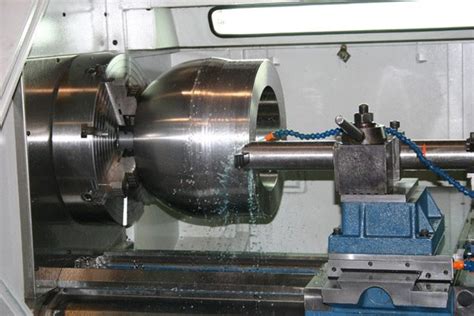

When it comes to manufacturing, there are two main methods of machining: CNC machining and manual machining. While both approaches can produce high-quality parts, they differ in terms of efficiency, accuracy, and cost. In this article, we'll explore the pros and cons of each method to help you decide which is right for your business. CNC Machining. To name a couple, CNC machining minimizes the amount of interaction between the operator and the machine tool, and significantly reduces the active machining time. But is this always the more efficient or fastest way to get a part done?

If you’re choosing which method to use for your business, here’s a detailed comparison between CNC machining vs Manual machining to help you make the best choice for your custom prototypes and end-use production parts.Explore the essential differences between CNC machining vs manual machining, including precision, speed, and skill requirements for optimal use Using CNC machines offers numerous advantages over manual machines, including higher precision, consistent quality across large production runs and the ability to perform complex cuts and shapes that would be difficult or impossible with manual machining. CNC machining offers several advantages over manual machining: • Precision and Accuracy: CNC machines operate with high precision and accuracy, consistently producing parts with tight tolerances. The computerized controls eliminate human errors and variations, ensuring precise and repeatable results.

While CNC Machining leverages automation and precision, manual machining offers traditional craftsmanship. Learn more about CNC Machining in our comprehensive guide. The decision between CNC vs manual machining affects more than production; it impacts efficiency, cost, and quality.

manual machining vs manual lathe

One of the main advantages - between CNC vs manual machining - is the reduced labour costs associated with CNC methods. With manual techniques, skilled operators are required to manually operate the machines, which can be time-consuming and costly.CNC machining is highly efficient and significantly faster compared to manual machining. Once the program is set, CNC machines can work continuously with minimal human intervention, enabling faster production rates. Conversely, manual machining can be time-consuming, especially for intricate designs or complex operations that require multiple .

CNC machining processes are much more precise than their manual counterparts and can reproduce identical components based on tolerance requirements with ease. The secondary advantage CNC machining provides over manual machining is . When it comes to manufacturing, there are two main methods of machining: CNC machining and manual machining. While both approaches can produce high-quality parts, they differ in terms of efficiency, accuracy, and cost. In this article, we'll explore the pros and cons of each method to help you decide which is right for your business. CNC Machining.

robert kaufman kaufman fusions metallic small leaf swirl holiday fabric

$199.99

average time savings cnc versus manual machining|manual cnc machining