cnc machine copper Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it . 【Ideal Outdoor Storage Box】Exterior: 49.41 in. L x 24.69 in. W x 27.56 with a lockable Lid. The deck box has a storage capacity of 120 gallons and can support a max static weight of 440 lbs. 【Easy to Use】The Outdoor storage container has portable side .

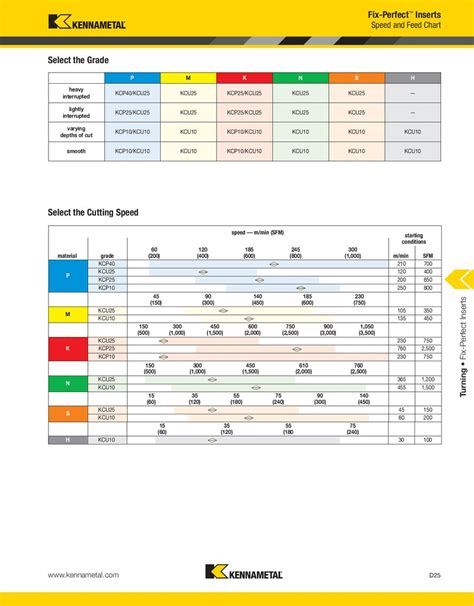

0 · turning copper speeds and feeds

1 · speeds and feeds for copper

2 · machinability of copper 110

3 · end mills for copper

4 · cutting speed for copper milling

5 · copper segregation procedure machine shop

6 · copper segregation policy machine shop

7 · copper machinability chart

This is a 1972 Aladdin brand metal lunch box depicting Woody Woodpecker. As the pictures show, this lunch box was well loved and used. It has rust in and out - mostly on the corners.

Discover essential tips and techniques for CNC Machining Copper in our comprehensive guide. Learn about copper’s unique material properties . Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it . Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and . Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, .

To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s .Understanding CNC Machines for Copper. CNC machines that are planned for copper machining function based on the same principles as those used in other metals but with some specific .

Why Copper for CNC Machining? Copper has a vast legacy that spans everything from coins to cookware. Yet, in CNC machining, copper is helpful for its aesthetics and mechanical properties.

AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in . Here’s the complete guide of CNC machining copper. – Copper 101: Copper 101 is pure copper, containing 99.9% copper. It is often used to make bronze and brass. – Bronze: Bronze is an alloy of tin, copper and phosphorus, . Discover essential tips and techniques for CNC Machining Copper in our comprehensive guide. Learn about copper’s unique material properties and how to effectively machine this versatile metal for optimal results. Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wear

Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes. Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications. To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results.

Understanding CNC Machines for Copper. CNC machines that are planned for copper machining function based on the same principles as those used in other metals but with some specific modifications to suit their unique attributes.

Why Copper for CNC Machining? Copper has a vast legacy that spans everything from coins to cookware. Yet, in CNC machining, copper is helpful for its aesthetics and mechanical properties. AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require . Here’s the complete guide of CNC machining copper. – Copper 101: Copper 101 is pure copper, containing 99.9% copper. It is often used to make bronze and brass. – Bronze: Bronze is an alloy of tin, copper and phosphorus, with good hardness and strength, and can be used to produce bearings and gears. Discover essential tips and techniques for CNC Machining Copper in our comprehensive guide. Learn about copper’s unique material properties and how to effectively machine this versatile metal for optimal results.

Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wear Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes. Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications.

To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results.Understanding CNC Machines for Copper. CNC machines that are planned for copper machining function based on the same principles as those used in other metals but with some specific modifications to suit their unique attributes.

Why Copper for CNC Machining? Copper has a vast legacy that spans everything from coins to cookware. Yet, in CNC machining, copper is helpful for its aesthetics and mechanical properties.

AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require .

cnc bending machines for sheet metal

turning copper speeds and feeds

speeds and feeds for copper

In addition to our mailboxes, we offer a wide range of house numbers and accessories designed to complement your aesthetic tastes perfectly. All of our house numbers undergo a five-step process to reveal the natural beauty of .

cnc machine copper|copper machinability chart