4th axis cnc machining 4-Axis machining, commonly known as 4-axis CNC machining, is a multi-axis machining process that utilizes CNC machines equipped with an additional rotary axis. This process involves a CNC machine that moves in .

Upload your CAD file for a price quote and order online. CNC services include .

0 · cnc 4th axis for sale

1 · 4th axis rotary cnc

2 · 4th axis for cnc mill

3 · 4 axis hobby cnc

4 · 4 axis desktop cnc mill

5 · 4 axis desktop cnc

6 · 4 axis cnc mill cost

7 · 4 axis cnc for sale

$31.66

4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four .4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.4-axis machining refers to a type of CNC (Computer Numerical Control) machining where a workpiece is processed through four different axes simultaneously. This method not only provides high precision and efficiency . A 4th axis on a milling machine is a powerful addition to its capabilities. To clarify, this extra rotation axis enables us to fabricate more complex parts..

4-Axis CNC machining is a revolutionary technology that has transformed the manufacturing industry. It involves using computer numerical control (CNC) machines to perform complex machining operations on a workpiece accurately . 4-Axis machining, commonly known as 4-axis CNC machining, is a multi-axis machining process that utilizes CNC machines equipped with an additional rotary axis. This process involves a CNC machine that moves in . A: A 4-axis CNC machine is a milling machine that can move a tool or a part in four different axes – typically the X, Y, Z, and a rotational axis known as the 4th axis. Q: What . This blog-post covers what 4 axis CNC machining is, its key benefits, differences between 3, 4 and 5 axis CNC machining, and ideal uses for 4 axis machining. What is 4 Axis CNC Machining? axis CNC machining .

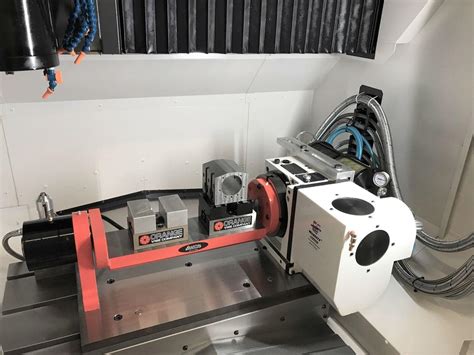

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. 4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours.

cnc 4th axis for sale

4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four different angles.4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.4-axis machining refers to a type of CNC (Computer Numerical Control) machining where a workpiece is processed through four different axes simultaneously. This method not only provides high precision and efficiency but also enables the creation of complex shapes and geometries.A 4th axis on a milling machine is a powerful addition to its capabilities. To clarify, this extra rotation axis enables us to fabricate more complex parts..

4-Axis CNC machining is a revolutionary technology that has transformed the manufacturing industry. It involves using computer numerical control (CNC) machines to perform complex machining operations on a workpiece accurately and efficiently. 4-Axis machining, commonly known as 4-axis CNC machining, is a multi-axis machining process that utilizes CNC machines equipped with an additional rotary axis. This process involves a CNC machine that moves in four different axes simultaneously.

A: A 4-axis CNC machine is a milling machine that can move a tool or a part in four different axes – typically the X, Y, Z, and a rotational axis known as the 4th axis. Q: What are the advantages of using a 4-axis CNC machine? A: Using a 4-axis CNC machine allows for more complex machining operations compared to a 3-axis machine. This blog-post covers what 4 axis CNC machining is, its key benefits, differences between 3, 4 and 5 axis CNC machining, and ideal uses for 4 axis machining. What is 4 Axis CNC Machining? axis CNC machining utilizes Computer Numerical Control . In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours. 4-Axis CNC machining involves multi-axis machining of workpiece material with CNC machines with an extra rotary axis. The 4-axis machining process utilizes any CNC machine that can simultaneously move at four different angles.4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

4-axis machining refers to a type of CNC (Computer Numerical Control) machining where a workpiece is processed through four different axes simultaneously. This method not only provides high precision and efficiency but also enables the creation of complex shapes and geometries.A 4th axis on a milling machine is a powerful addition to its capabilities. To clarify, this extra rotation axis enables us to fabricate more complex parts..

4th axis rotary cnc

4-Axis CNC machining is a revolutionary technology that has transformed the manufacturing industry. It involves using computer numerical control (CNC) machines to perform complex machining operations on a workpiece accurately and efficiently.

4-Axis machining, commonly known as 4-axis CNC machining, is a multi-axis machining process that utilizes CNC machines equipped with an additional rotary axis. This process involves a CNC machine that moves in four different axes simultaneously.

A: A 4-axis CNC machine is a milling machine that can move a tool or a part in four different axes – typically the X, Y, Z, and a rotational axis known as the 4th axis. Q: What are the advantages of using a 4-axis CNC machine? A: Using a 4-axis CNC machine allows for more complex machining operations compared to a 3-axis machine.

4th axis for cnc mill

4 axis hobby cnc

These are American (Brown & Sharpe) Gauges.

4th axis cnc machining|4 axis cnc mill cost