types of electrical cable enclosures Explore the eight most common electrical enclosure types and how they’re used. From NEMA ratings to materials, we give you the basics. Find sheet metal at Lowe's today. Shop metal sheets of steel, aluminum, tin, and a variety of materials. Shop in store or online at Lowes.com.

0 · typical residential electrical supply cabinet

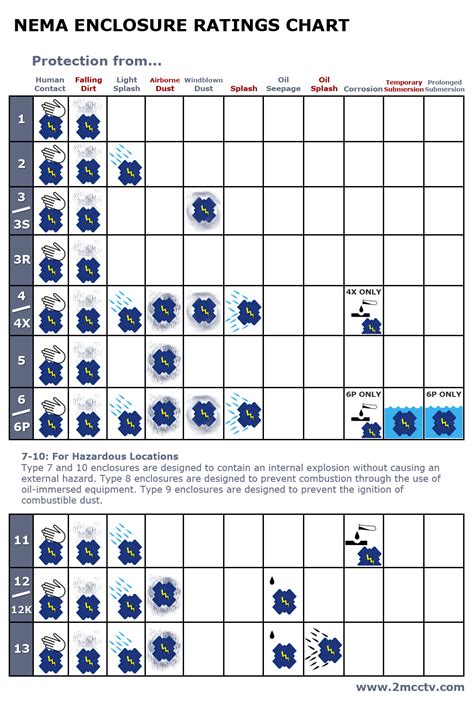

1 · nema ratings chart pdf

2 · nema 1 vs 3r enclosure

3 · nema 1 vs 12 enclosure

4 · explosion proof electrical enclosures

5 · enclosures for electrical equipment

6 · electrical panel enclosure types

7 · different types of wiring enclosures

CNC machines are machine tools that cut or move material as programmed on the controller, as described above. The type of cutting can vary from plasma cutting to laser cutting, milling, routing, and lathes.

typical residential electrical supply cabinet

mecanizado cnc compañías

nema ratings chart pdf

Explore the eight most common electrical enclosure types and how they’re used. From NEMA ratings to materials, we give you the basics.Some of the basic types of electrical enclosures that you’ll find on the market . Understanding the various types of electrical enclosures is crucial for selecting the right one for your needs. They can be broadly categorized into metal, non-metallic, and specialty enclosures. Each type has its advantages, .

These types of electrical enclosures are constructed to house electrical instruments, equipment and controls within an outdoor, weatherproof surrounding. The . Today’s post offers a comprehensive guide to electrical enclosures, including the various types, the significance of enclosure ratings and construction materials, and how to choose the proper electrical cabinets or .The purpose of this document is to provide general information on the definitions of NEMA Enclosure Types to architects, engineers, installers, inspectors and other interested parties. .

Discover how to choose the ideal electrical enclosure for your industry. Our comprehensive guide covers types, materials, compliance, and real-world case studies to guide your selection process.Electrical Enclosures Overview and Types. Sloped top Enclosures: Typically wall-mounted, floor-mou ted or freestanding units designed with a 20° slope on the top portion of the enclosure .

mechnical cnc turning parts factory

This comprehensive guide aims to shed light on the different types of electrical enclosures, their applications, and what to consider when making a selection. What is an .K+2.99.49

.792.790.79

Junction Boxes: Junction boxes are the most common type of electrical enclosure to protect electrical connections and house wiring. They are versatile and come in various .

Electrical Equipment Cable Accessories Protection Box Type 1, 2. 794835 CABLE ENCLOSURE ELECTRIC FRP, 100X100X100MM. IMPA Code: 794835. UOM: PCS. MTML UOM: PCE. FRP (Fiberglass Reinforced Plastic) box for treatment of cable end for use indoor and outdoor. Waterproof and dustproof construction with inner packing.

An insert clamps the cable in place and provides more strain relief than standard snap-in cord grips for building cable. Use to connect building cable for dry locations, also known as Romex type NM-B cable, to enclosures and outlet boxes by pushing these grips into a knockout. For technical drawings and 3-D models, click on a part number.Critchley Z-Type Rail Relay Slide-On Cable Markers; Easi-Lok LFH Slide-On Cable Markers; Critchley Z-Type Slide-On Cable Markers; See All Rail Products; SERVICES. . Electrical enclosures are a great way to keep your electrical components safe and secure. They provide protection from dust, water, and other environmental elements that could .Electrical Fixing and Fastening (1) EMC (16) Factory Automation and Process Control (1363)A cable enclosure is designed to protect its contents (cables, connectors, equipment etc.) against external influences. . For electrical installations, certain cable types are drawn into pits. AS/NZS 3000 chiefly defines these cables as Category A underground wiring systems and dependent on the cable type, they are housed in a cable route .

Electrical enclosure ratings are fundamental factors when it comes to selecting enclosures for particular applications and locations. They define the environmental and safety conditions that an enclosure is built for, as well as its general suitability for certain types of electrical equipment.

This type of electrical enclosure is commonly used to protect one or more wiring connections and designed for use as surface-mounted junction boxes, service boxes, switch boxes and cutout boxes. These boxes commonly include pre-punched knockouts for easier cable entry. Pushbutton Enclosures.Study with Quizlet and memorize flashcards containing terms like Explosionproof equipment and wiring shall not be required and shall not be acceptable in Class II locations unless also identified for such locations., Which of the following wiring methods is permitted to be used in Class II, Division 1 locations?, Identified elevator cable Type EO, Type ETP, or Type ETT, shown under . Cable Glands. Cable glands secure and attach the end of an electrical cable to the equipment. They are used for strain relief and to connect cables to electrical devices, enclosures, or junction boxes, ensuring that the cables are securely fastened and protected from environmental factors. Wire Connectors and Terminals

NEMA Type 7 Enclosure. A NEMA Type 7 Enclosure is for indoor use in locations classified by the NEC® 500 as Class I, Groups A, B, C, or D. A NEMA Type 7 enclosure shall be capable of withstanding the pressures resulting from an internal explosion of specified gases, and contain such an explosion sufficiently that an explosive gas-air mixture existing in the atmosphere . The NEMA Type 3 electrical enclosure is designed for either indoor and outdoor use. The Type 3 enclosure offers a higher level of protection than both NEMA type 1 & NEMA type 2. The NEMA type 3 enclosure offers protection against personnel coming into contact with the enclosures components, but also has a rubber gasket that adds a higher level of protection .

Electrical Enclosure Mounting Channels. Position components inside electrical enclosures without drilling holes, which can leak. 9 products. Raceway. Route and guard wiring along surfaces in your facility. 54 products. HMI Covers. Access HMI devices and other controls mounted to an enclosure while keeping out liquids and dust.

Some of the basic types of electrical enclosures that you’ll find on the market today include: Indoor Enclosures; Outdoor Enclosures; Hinged Enclosures . NEMA 12K enclosures are similar to Type 12, but include pre-constructed knockouts to accommodate cables, antennas and other equipment. Indoor/Outdoor: Indoor; Solid Ingress Protection .

K6 Outline the various types of electrical cable enclosure and support systems used, and their typical applications When cables cannot be protected within any form of installation structure such as being installed behind a wall or above a ceiling they can be protected by things like conduit or trunking or tray work systems that allow them to be .

Electrical enclosures can be customized to your exact colour and specification, whether it is to pre-drill holes or cutouts, or add an extra door. . Enclosures for commercial installations include junction boxes, basic panels, cable troughs, transformer cabinets, drive cabinets, cable support and wire mesh cable tray products. Parts and components of an electrical cable. For an electrical cable to work correctly, various elements are needed. Each of these components performs a unique function to ensure the passage of electrical current. . Cable connectors for termination are used to attach or finish the ends of wires in a way that ensures a stable connection. They are designed to handle specific tasks like splicing, grounding, or attaching wires to terminals. These connectors are standard in panels, junction boxes, and other setups where secure wiring is crucial. In this article, let's go over all of the .

Nema Enclosures standard and custom powder coated carbon steel, 304 stainless steel, 316 stainless steel and 5052 aluminum wire trough electrical enclosures house and protect wires from water and corrosive elements and offer excellent protection in a number of applications. All trough type electrical enclosures are NEMA rated, UL listed and/or .Based on Industrial Application: Electromagnetic Compatibility (EMC) Cable Glands, Marine Cable Glands, Electric Cable Glands, Fire-Stop Cable Glands, Explosion-Proof Cable Glands. Based on Standard: Type A Cable Glands (A1, A2, A3, A4), Type B Cable Glands, Type C Cable Glands, Type D Cable Glands (D1, D2), Type E Cable Glands (E1, E2). Understanding the various types of electrical enclosures is crucial for selecting the right one for your specific needs. Let's take a closer look at some common classifications. . Cable Management. Built-in cable management features can simplify the installation process and make future maintenance easier.Electrical Equipment Cable Accessories Protection Box Type 1, 2. 794839 CABLE ENCLOSURE ELECTRIC FRP, 200X200X125MM. IMPA Code: 794839. UOM: PCS. MTML UOM: PCE. FRP (Fiberglass Reinforced Plastic) box for treatment of cable end for use indoor and outdoor. Waterproof and dustproof construction with inner packing.

Triple Compartment Trunking: Can be used when all three types of source cable i.e. electrical, data, and telephone cables.. Construction of Electrical Trunking. A trunking is an enclosure provided for the protection of cables which is normally square or rectangular in cross-section, having one removable side. Forming and assembling electrical cable enclosure and support systems Unit Questions 1. Describe the. AI Chat with PDF. Expert Help. Study Resources. . Finally , another type of cable enclosure which I have come across is metal tray work . This may be used in situations where you would need to run bigger cables , too large for trunking , into .Electro polished enclosure (control station), explosion-proof A municipal electrical enclosure Allen Bradley programmable logic controller (PLC) installed in an electrical enclosure. An electrical enclosure is a cabinet for electrical or electronic equipment to mount switches, knobs and displays and to prevent electrical shock to equipment users and protect the contents from the .

Electrical Equipment Cable Accessories Protection Box Type 1, 2. 794836 CABLE ENCLOSURE ELECTRIC FRP, 150X150X100MM. IMPA Code: 794836. UOM: PCS. MTML UOM: PCE. FRP (Fiberglass Reinforced Plastic) box for treatment of cable end for use indoor and outdoor. Waterproof and dustproof construction with inner packing. Types of Electrical Enclosures. The world of electrical enclosures is diverse, with various types available to suit different needs and environments. From small junction boxes to large industrial cabinets, the range is extensive. . An electrical cable enclosure is a protective casing designed to house and safeguard electrical cables and wires .Companies and individuals utilize cable entry systems to route pneumatic and hydraulic hoses, corrugated conduits or electrical cables into control panels, electrical enclosures, machines and switch cabinets. Additionally, you can find them in roll stock, ships and heavy-duty vehicles.

The story of CNC machining dates back to the 1940s and 1950s, originating from the need for high-precision machining for the defense and aerospace industries during and after World War II. The first numerical control machines were born out of the collaboration between the Massachusetts Institute of Technology (MIT) and the United States Air Force.

types of electrical cable enclosures|nema 1 vs 3r enclosure