cnc machine bedways The Kent CNC LL Series Extra Long 5 Bed Way Heavy Duty Turning Centers allow for seamless turning from tip to tip with its 5 individual . Shielded metal arc welding (SMAW), commonly referred to as stick welding, is one of the welding processes that is applicable to thin materials as long as the right procedures and equipment are used. In this paper, we develop basic tricks and techniques that are largely aimed at people who are new to the application of stick welding to thin sheets.

0 · Why Kingston

1 · Machine beds

2 · Machine Ways – Detroit Edge Tool Company

3 · Lathe Bed

4 · Colchester Multiturn 1000

5 · CNC Machine Beds: The Foundation of Precision

6 · CNC Lathes

7 · CNC 5 Bed Way Heavy Duty Extra Long Turning Centers

8 · CK6146ZX CNC Lathe, Products Show, YANCHENG

9 · 22″ x 80″ New Summit CNC Lathe Flat Bed

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.

Few machine tool components are more fundamental than the way system, which provides the interface between moving and stationary elements of the machine. Machine Ways can either be flame hardened or through hardened to 58-62 RC, and determine the basic accuracy of machine tools. Ways are robust . See more

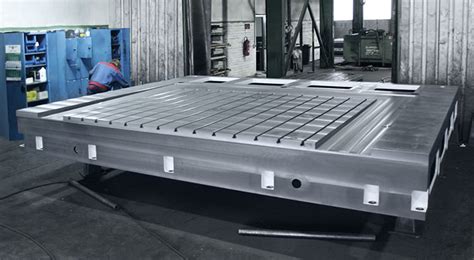

Every industry has its own machines that are reliant on machine way or rail guides. Here are a few different industries that use different guide systems: See more Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and worktable. A robust machine bed .

The Colchester Multiturn CNC flat-bed centre lathe range is designed for fast, high-quality repeatability, accuracy and surface finish to exacting toolroom accuracy standards (DIN 8605), .

The Kent CNC LL Series Extra Long 5 Bed Way Heavy Duty Turning Centers allow for seamless turning from tip to tip with its 5 individual .This New CNC Lathe features: •Hardened and Precision Ground Bedways •Precision Ground Ballscrews •Electric Handwheels for Manual Operation •Combination Manual/Full CNC Operation •Guarding Package •Auto-Timed .Our slant bed lathes and toolroom lathes feature a wide selection of lengths and spindle sizes. The ML Series 2-axis toolroom lathes come standard with full box ways and removable gap .

5) The surface of the bedways is supersonic frequency hardened and precision ground with a long service life. 6) The spindle bore size is 80mm. The spindle system is high in the rigidity and accuracy.The Uniport machines have just what you need for multi-sided machining of large voluminous components such as machine beds. These casted parts come in all shapes and dimensions. .Bedways or simply ways are linear bearing elements that provide a path of motion for the carriage and tailstock of the lathe. Bedways can have several configurations including box ways, v-ways, dovetail ways and may be used .

We grind all our bedways up to 280” in house and employ the best master hand scrapers to finish every carriage and bedway that ends up on your floor. And the Kingston design? It remains a classic.DETCO’s machine way manufacturing facilities have the latest in CNC machining centers and grinders, which allows DETCO the ability to produce tight tolerance machine ways, bed ways, lathe ways, and rails demanded by machine tool builders. Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and worktable. A robust machine bed ensures stability, reduces vibrations, and contributes to the overall accuracy and longevity of the machine. Historical Evolution of Machine BedsThe Colchester Multiturn CNC flat-bed centre lathe range is designed for fast, high-quality repeatability, accuracy and surface finish to exacting toolroom accuracy standards (DIN 8605), which ultimately significantly reduces component production costs.

The Kent CNC LL Series Extra Long 5 Bed Way Heavy Duty Turning Centers allow for seamless turning from tip to tip with its 5 individual bed way structure. The 5 bed way design keeps the carriage, tailstock and steady rest on their own ways.This New CNC Lathe features: •Hardened and Precision Ground Bedways •Precision Ground Ballscrews •Electric Handwheels for Manual Operation •Combination Manual/Full CNC Operation •Guarding Package •Auto-Timed Metered Lube System •Automatic Gear Range Selection •3 Jaw Chuck w/ 2 Piece Jaws •Steady Rest w/ Rollers

Why Kingston

Our slant bed lathes and toolroom lathes feature a wide selection of lengths and spindle sizes. The ML Series 2-axis toolroom lathes come standard with full box ways and removable gap bed on every machine. This provides a more rigid and stable platform than V-type bed ways.5) The surface of the bedways is supersonic frequency hardened and precision ground with a long service life. 6) The spindle bore size is 80mm. The spindle system is high in the rigidity and accuracy.The Uniport machines have just what you need for multi-sided machining of large voluminous components such as machine beds. These casted parts come in all shapes and dimensions. The flexibility and capabilities of the Uniport machines are ideal for many large machining tasks.Bedways or simply ways are linear bearing elements that provide a path of motion for the carriage and tailstock of the lathe. Bedways can have several configurations including box ways, v-ways, dovetail ways and may be used with ball or roller bearings on some lathes.

jah wobble keith levene metal box in dub

We grind all our bedways up to 280” in house and employ the best master hand scrapers to finish every carriage and bedway that ends up on your floor. And the Kingston design? It remains a classic.DETCO’s machine way manufacturing facilities have the latest in CNC machining centers and grinders, which allows DETCO the ability to produce tight tolerance machine ways, bed ways, lathe ways, and rails demanded by machine tool builders.

Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and worktable. A robust machine bed ensures stability, reduces vibrations, and contributes to the overall accuracy and longevity of the machine. Historical Evolution of Machine Beds

jack in the box grand junction colorado

Machine beds

The Colchester Multiturn CNC flat-bed centre lathe range is designed for fast, high-quality repeatability, accuracy and surface finish to exacting toolroom accuracy standards (DIN 8605), which ultimately significantly reduces component production costs.The Kent CNC LL Series Extra Long 5 Bed Way Heavy Duty Turning Centers allow for seamless turning from tip to tip with its 5 individual bed way structure. The 5 bed way design keeps the carriage, tailstock and steady rest on their own ways.This New CNC Lathe features: •Hardened and Precision Ground Bedways •Precision Ground Ballscrews •Electric Handwheels for Manual Operation •Combination Manual/Full CNC Operation •Guarding Package •Auto-Timed Metered Lube System •Automatic Gear Range Selection •3 Jaw Chuck w/ 2 Piece Jaws •Steady Rest w/ Rollers

Our slant bed lathes and toolroom lathes feature a wide selection of lengths and spindle sizes. The ML Series 2-axis toolroom lathes come standard with full box ways and removable gap bed on every machine. This provides a more rigid and stable platform than V-type bed ways.

5) The surface of the bedways is supersonic frequency hardened and precision ground with a long service life. 6) The spindle bore size is 80mm. The spindle system is high in the rigidity and accuracy.The Uniport machines have just what you need for multi-sided machining of large voluminous components such as machine beds. These casted parts come in all shapes and dimensions. The flexibility and capabilities of the Uniport machines are ideal for many large machining tasks.Bedways or simply ways are linear bearing elements that provide a path of motion for the carriage and tailstock of the lathe. Bedways can have several configurations including box ways, v-ways, dovetail ways and may be used with ball or roller bearings on some lathes.

Machine Ways – Detroit Edge Tool Company

You will need to pull additional cable, post pictures of the insides of your boxes and we can advise. Ok, so now all travelers are marked, as are any white non-neutral wires. We know we have power coming through a 3-way box, because white wires remain.

cnc machine bedways|Colchester Multiturn 1000